These trucks are engineered with precision and durability in mind. The robust chassis, constructed from high-strength steel, offers excellent stability, allowing safe operation on various terrains, be it a smooth construction site or uneven outdoor landscape.

Equipped with a telescopic boom, they provide an impressive vertical and horizontal reach, enabling workers to access hard-to-reach areas with ease. The platform is spacious, accommodating multiple operators and their tools comfortably, enhancing work efficiency. The hydraulic system is highly responsive, ensuring smooth and controlled lifting motions.

Safety features are of utmost importance. Anti-slip surfaces on the platform, emergency stop buttons, and safety harness attachments are incorporated to protect operators at all times.

| The specification of ISUZU 14M Boom Lift Truck | |||

| Name | ISUZU 14M Boom Lift Truck | ||

| Item | Specifications | Item | Specifications |

| Gross Weight (kg) | 6970 | ||

| Overall dimensions (mm) | 7730×2020×3370 | Curb Weight (kg) | 6645 |

| Wheelbase (mm) | 3308 | Approach / Departure Angle(°) | 20/15 |

| Front Track (mm) | 1503, 1485, 1519 | Rear Track (mm) | 1494, 1516 |

| Front/Rear Overhang (mm) | 1040/2082 | Axle Load (kg) | 2780/4190 |

| Number of axles | 2 | Number of Tires | 6 |

| Traction system | 4×2 | Max speed (km/h) | 99 |

| ABS | Contain | Tire Specification | 7.00-16,7.00R16 |

| Paint | yellow | Allowable Cab Passengers | 2+3 |

| Leaf Spring | 6/6+5 | ||

| Chassis | |||

| Brand | ISUZU | ||

| Emission Level | Euro 5 | ||

| Engine (Diesel) | |||

| Superstructure | |||

| Max Operation Height: 16m, 360° hydraulic Rotation, 3section folding arm, Single hydraulic lifting cylinder, bidirectional balance valve, Electronically Control System lift arm, 1000kg telescoping hook, 4pcs of hydro cylinder adjustable manual landing leg with both way hydraulic lock. | |||

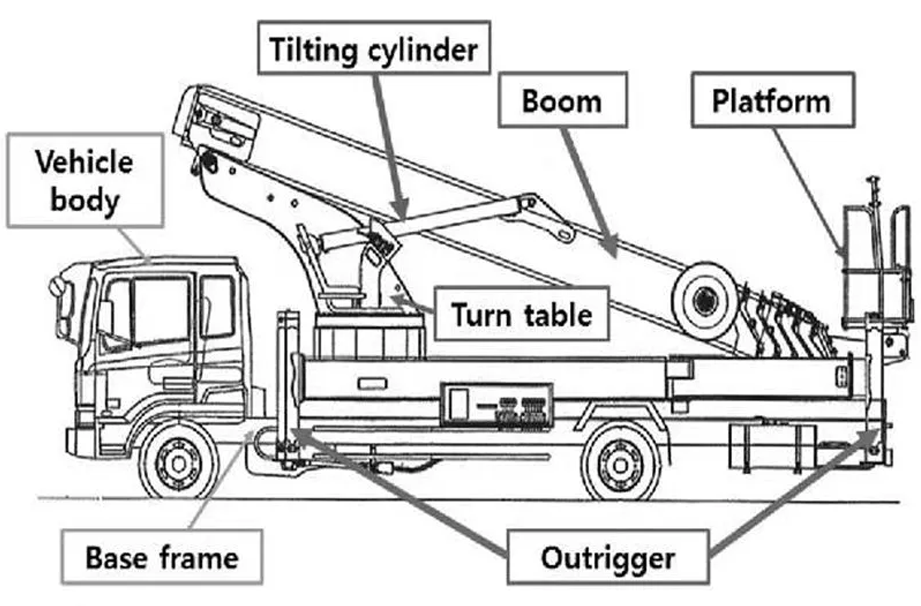

1. The chassis is the foundation of the boom lift truck. It's typically made of heavy-duty steel to support the entire weight of the vehicle, including the boom, platform, and any load it's carrying.

2. The boom is the most distinctive component. It's usually a telescopic or articulating structure. Telescopic booms are made up of multiple nested sections that can extend and retract to reach different heights and distances.

3. The platform is where operators stand or place equipment. It's designed to be spacious enough to accommodate workers and their tools. Made of strong, non-slip materials such as steel grating or composite materials, it ensures the safety of the operators.

4. The hydraulic system is the heart of the boom lift truck's movement. It consists of a hydraulic pump, usually driven by the vehicle's engine, and a series of hydraulic cylinders and valves.

5. The control system enables the operator to manipulate the boom lift truck. It can be either a simple set of joysticks or a more complex electronic control panel.

6. In some cases, boom lift trucks are equipped with outriggers. These are extendable legs that can be deployed to provide additional stability, especially when the boom is fully extended or when the truck is operating on uneven ground.

1. Determine the maximum height and horizontal reach you need for your specific tasks. Consider the height of the structures you'll be working on, such as buildings, bridges, or power lines.

2. Assess the weight of the workers, tools, and materials that will be on the platform simultaneously. The platform capacity of boom lift trucks varies, and it's crucial to choose a model that can safely support the intended load.

3. Consider the type of terrain where the boom lift truck will be used. If it's a construction site with rough and uneven ground, a truck with large, all-terrain wheels or tracks may be more suitable.

4. Boom lift trucks can be powered by different sources. Diesel-powered trucks are more suitable for outdoor and heavy-duty applications where a long-running time and high power output are required.

5. Look for essential safety features such as non-slip platforms, guardrails, and safety harness attachment points. The lift should also have an emergency stop button and a reliable braking system.

6. Compare the initial cost of different boom lift trucks. However, don't forget to consider the long-term maintenance costs.

Boom lift trucks are designed with a telescopic or articulating boom that provides a significant vertical and horizontal reach.

These trucks have a robust chassis made of high-strength materials like steel. The chassis provides a stable base for the boom and the platform, ensuring safe operation even when the boom is fully extended.

The platform of a boom lift truck is a key feature. It is usually spacious enough to accommodate multiple workers and their tools.

The hydraulic system of the boom lift truck enables precise and smooth movement of the boom and platform.

Boom lift trucks incorporate a variety of safety features. In addition to the non-slip platform and guardrails, they often have safety harness attachment points to further protect the operators in case of a fall.

These trucks are designed to be mobile and maneuverable, allowing them to be easily transported to different job sites.