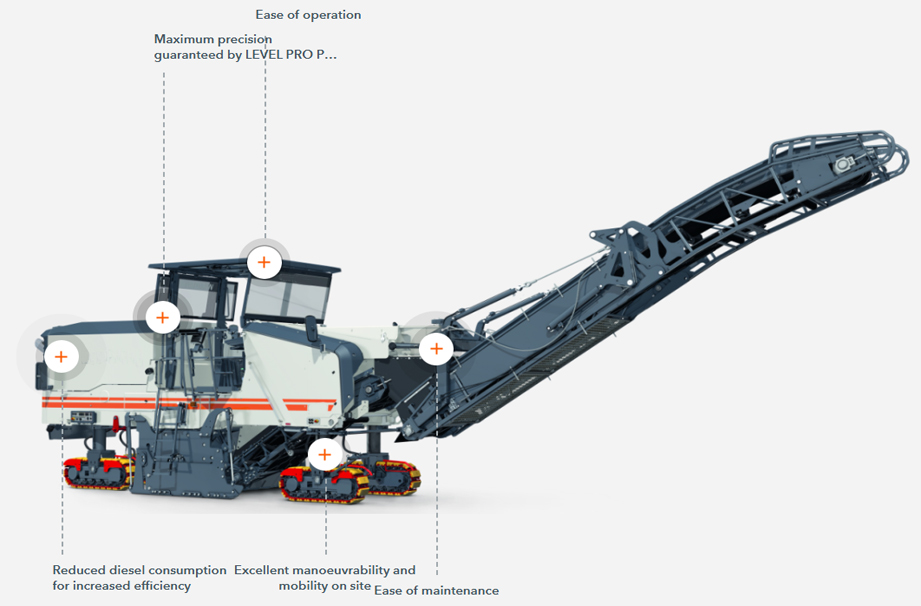

A cold milling machine is essential for road renovation. It sports a powerful diesel engine that drives a rotating milling drum fitted with tough carbide-tipped cutters. These cutters can accurately and rapidly remove old asphalt or concrete layers, producing uniform milled material. The operator's cabin offers excellent visibility and user-friendly controls. With adjustable milling depth and width, it flexibly meets diverse project demands. Its high efficiency not only saves time but also paves the way for laying new, smooth pavement surfaces.

| Picture |  |  |  |  |

| General parameters | ||||

| Model | PM102 | PM102 - Wheel | PM200 | PM201 |

| Engine | ||||

| Model | Cat® C7 ACERT™ | Cat® C7 ACERT™ | Cat® C18 ACERT | Cat® C18 ACERT |

| Rated power (kW) | 168 | 168 | 429 | |

| Dimension | ||||

| L×W×H (whole machine) (mm) | 10700×1980×3400 | 10700×2000×3400 | 13940×2900×3950 | 15100×2810×5040 |

| L×W×H (conveyor, top folded) (mm) | 5330×2500×3100 | 8500×2400×3100 | 7500×2500×3150 | |

| Maximum feed height (mm) | 4800 | 4800 | 3950 | 2980 |

| Weight parameters | ||||

| Operating weight (when tank is full) (kg) | 17600 | 17100 | 30100 | 35110 |

| Front track load (with tank full) (kg) | 15600 | 19310 | ||

| Rear track load (with tank full) (kg) | 14500 | 15800 | ||

| Transportation weight (kg) | 16400 | 16400 | 28000 | 30840 |

| Front track transport weight (kg) | 12650 | 16655 | ||

| Rear track transport weight (kg) | 15350 | 14185 | ||

| Shipping weight (with tank empty) (kg) | 17100 | 16400 | 28000 | |

| Feeding systems | ||||

| Aggregate Belt Machine Rate (m/min) | 252 | 252 | 300 | 189 |

| Width of aggregate belt conveyor (mm) | 550 | 550 | 800 | 1020 |

| Width of discharge belt conveyor (mm) | 600 | 600 | 800 | 915 |

| Maximum unloading belt conveyor speed (m/min) | 252 | 252 | 300 | 231 |

| Unloading belt conveyor swing angle (°) | 41 | 41 | 48 | 45 |

| Unloading conveyor length (mm) | 6300 | 6300 | ||

| Operating parameters | ||||

| Travel speed (km/h) | 6.4 | 6.4 | 5.9 | 6 |

| Maximum milling width (mm) | 1000 | 1000 | 2010 | 2100 |

| Maximum milling depth (mm) | 305 | 305 | 320 | 305 |

| Milling speed (m/min) | 46 | 27 | 38 | 40 |

| Minimum Ground Clearance (mm) | 4800 | 4600 | 4750 | |

| Inner Turning Radius (mm) | 3450 | 2100 | ||

| Minimum milling height (mm) | 2380 | 2380 | ||

| Milling rollers | ||||

| Number of tools (pcs) | 98 | 97 | 178 | 147 |

| Maximum milling depth (mm) | 305 | 305 | 320 | |

| Milling width (mm) | 1000 | 1000 | 2010 | |

| Fuel capacity | ||||

| Fuel tank (L) | 400 | 400 | 1100 | |

| Hydraulic oil tank (L) | 400 | 1100 | 946 | |

| Water Tank (L) | 1060 | 1060 | 3500 | 3787 |

1. The frame is the backbone of the machine, typically made of high-strength steel. It provides the necessary rigidity to support all other components and withstand the vibrations and forces generated during milling.

2. Milling Drum: This is the heart of the operation. It rotates at high speed and is outfitted with a multitude of carbide-tipped cutters.

3. Engine: A robust diesel engine serves as the power source. It needs to generate sufficient horsepower to drive the milling drum and move the machine forward.

4. Conveyor System: Responsible for transporting the milled material away from the cutting area. It usually consists of a belt conveyor that can be adjusted in height and angle.

5. Operator's Cab: Designed with the operator's comfort and safety in mind. It has large windows that provide excellent visibility of the milling area, the drum, and the surrounding environment.

6. Hydraulic System: Powers multiple functions of the cold milling machine. It controls the movement of the milling drum, the adjustment of the conveyor, and the operation of other auxiliary components.

7. Water Spray System: Essential for cooling the cutters and suppressing dust. As the milling drum rotates and the cutters engage with the pavement, a significant amount of heat is generated.

1. Width: Determine the typical width of the area you need to mill. Cold milling machines come in a variety of milling widths.

2. Depth: The required milling depth also varies depending on the project. If you're only removing a thin surface layer for resurfacing, a machine capable of milling to a depth of a few centimeters might be enough.

3. Engine Power: The engine is the heart of the cold milling machine. Look for a machine with an engine that provides enough power to handle the milling tasks efficiently.

4. Milling Drum Speed and Torque: The speed and torque of the milling drum affect the milling quality and productivity.

5. Conveyor Capacity: The conveyor system's capacity determines how quickly and effectively the milled material can be removed from the work area.

6. Material Discharge Options: Check if the cold milling machine offers flexible material discharge options. Some machines can discharge the material to the side, rear, or even both directions.

7. Cab Design: The operator's cab should be comfortable and well-equipped. It should have an ergonomic seat, good visibility from all sides, and climate-control systems to provide a comfortable working environment.

8. Safety Features: Look for safety features such as roll-over protection structures (ROPS) and falling-object protection structures (FOPS).

9. Track or Wheel System: Cold milling machines can have either a track or wheel system. Track-based machines offer better stability and traction, especially on uneven or soft surfaces.

10. Turning Radius and Maneuverability: A small turning radius allows the cold milling machine to be more maneuverable, which is important for working in tight spaces such as intersections or around obstacles.

High-Quality Milling Drum: The milling drum is a central component. It's equipped with carbide-tipped cutters that are durable and sharp.

Adjustable Milling Parameters: The milling depth and width can be adjusted according to the specific requirements of the project.

Conveyor for Material Removal: A well-designed conveyor system is essential. It efficiently transports the milled material away from the cutting area.

Large-Capacity Material Handling: The conveyor and overall material-handling system have the capacity to deal with a significant volume of milled material.

Powerful Engine: Cold milling machines are typically powered by diesel engines. These engines are powerful and provide the necessary energy to drive the milling drum and move the machine forward.

Efficient Propulsion System: The propulsion system allows the machine to move smoothly and at an appropriate speed during the milling process.

Comfortable Operator's Cab: The operator's cab is designed with comfort and safety in mind. It has excellent visibility, with large windows that provide a clear view of the milling area, the drum, and the surrounding environment.

Intuitive Controls: The controls in the cab are user-friendly and intuitive. The operator can easily adjust settings such as milling depth, width, drum speed, and conveyor position through levers, buttons, or a control panel.