A concrete mixer truck is a crucial vehicle in the construction industry. It features a large rotating drum on its chassis. The drum is designed to mix cement, aggregates, water, and other additives thoroughly. With a powerful engine and a reliable transmission system, it can transport the freshly mixed concrete to construction sites. The truck's exterior is usually made of durable metal to withstand harsh working conditions. Its unique design and functionality ensure the even consistency of concrete during transit, facilitating efficient and high-quality construction work.

| Specification of Sinotruk 6*4 12m3 Concrete mixer Truck | ||

| Drive model | 6x4/LHD | |

| Max. Driving Speed(km/h) | 75 | |

| Cabin | Passengers Allowed in front row | 3 persons |

| Vehicle | Curb Weight(kg) | 12770 |

| Overall Dimensions(L x W x H)(mm) | 8600*2500*3700 | |

| Approach/Departure angle(°) | 21/15 | |

| Wheel Base(mm) | 3600+1350 | |

| Overhang (front/rear) (mm) | 1320/2330 | |

| Wheel Track (front/rear) (mm) | 1995/1820/1850 | |

| Axle charge(front/rear)(ton) | 43664 | |

| Tire | 12.00R20 ,10 wheels with one spare tire | |

| Engine | Model | WD615.69 |

| Air-in Type | TURBO, inter-cooling | |

| Engine Type | Vertical, In-line, water-cooling, 4 strokes | |

| Fuel | Diesel | |

| MAX Power(HP) | 336 | |

| Emission standard | Euro Ⅱ | |

| Cylinder Number | 6 | |

| Rated Speed(RPM) | 2200 | |

| MAX Torque(N.M) | 1350 | |

| Displacement(L) | 9.726 | |

| Gear Box | Model | HW15710 |

| Shift | 10manual | |

| Reverse shift | 2 | |

| Rated Speed(RPM) | 2600 | |

| MAX Torque(N.M) | 1500 | |

| Upper part | ||

| Mixing Drum | Capacity | 14cubic meters |

| Shell Material | Alloy steel(special wear- resistant material, | |

| enhance the service life of tank at least 3 times) | ||

| Lining Material | 16Mn 6mm alloy steel | |

| End plate Material | 8mm alloy steel | |

| Blade Material | Bao Steel 520 5mm alloy steel (equipped with | |

| wear-resistant strip, longer service time) | ||

| Feed Rate (m3/min) | ≥3 | |

| Discharging Rate(m3/min) | ≥2 | |

| Discharging Residual Ratio(%) | ≤0.5 | |

| Discharging Rage | 180° | |

| Operation mode | Control panel in cabin or on each side the | |

| mixer tank | ||

| Hydraulic system | Hydraulic pump | America Sauer or America Eaton |

| Hydraulic motor | America Sauer or America Eaton | |

| Radiator | Chinese brand | |

| Reducer | Italy PMP or Italy Bonfiglioli or Germany ZF | |

| Water Tank | Volume(L) | 400 |

| Supply system | Air-pressure | |

| Description | Provide water to concrete during transportation | |

| and to cool down the hydraulic system. With | ||

| wash-hand device. | ||

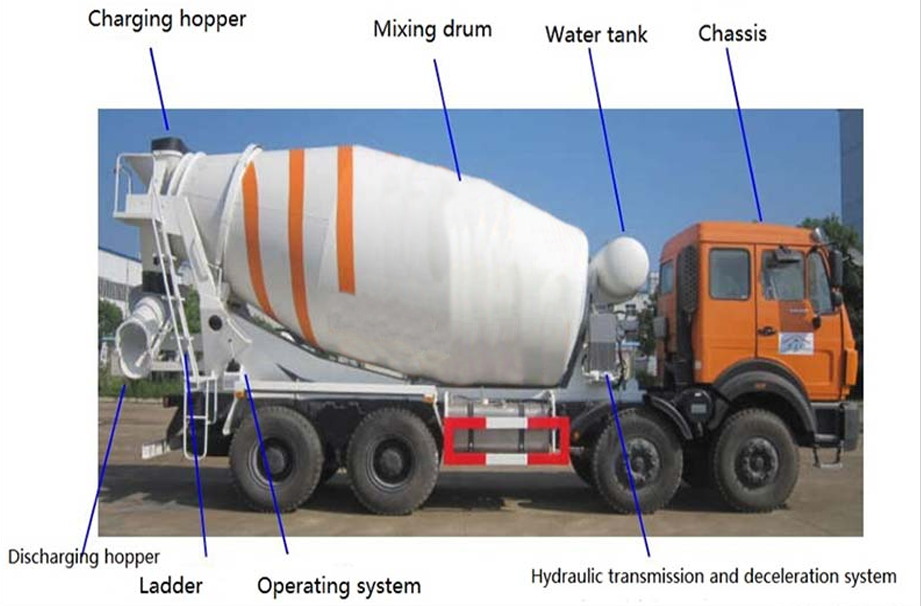

1. The chassis is the base frame of the concrete mixer truck. It is usually a heavy-duty truck chassis that provides structural support. It's designed to handle the weight of the mixer drum, the concrete it carries, and other components.

2. The mixer drum is the most prominent component. It's a large, cylindrical, and usually made of steel with a thick enough wall to withstand the abrasion of the concrete and the forces during rotation. The inside of the drum is fitted with mixing blades.

3. A key part of the concrete mixer truck is the hydraulic system. It powers the rotation of the mixer drum. The system consists of a hydraulic pump, usually driven by the truck's engine, hydraulic motors, hoses, and valves.

4. The water system is essential for adding the correct amount of water to the concrete mix. It includes a water tank, which is usually located on the truck. The tank has a capacity that varies depending on the size of the truck and the intended use.

5. The transmission system connects the engine to the axles and the hydraulic pump. It allows the power generated by the engine to be transferred efficiently to different parts of the truck.

6. The control cabin is where the operator sits and controls the various functions of the concrete mixer truck. It's equipped with a dashboard that has gauges and controls for monitoring and operating the truck's movement, the rotation of the mixer drum, and the water supply system.

1. The capacity of the mixer drum is a crucial factor. It's measured in cubic yards or cubic meters. For small-scale construction projects such as residential building renovations or small patio installations, a truck with a capacity of 2-6 cubic yards (1.5-4.6 cubic meters) might be sufficient.

2. There are different types of discharge systems. The most common ones are the chute-type and the conveyor-belt-type. The chute-type is simple and cost-effective. It's suitable for projects where the concrete needs to be discharged at a relatively short distance and height.

3. The quality of the truck's chassis affects its durability and mobility. Look for a strong and well-built chassis made of high-quality steel.

4. The efficiency of the mixing system is vital. The mixer drum should have a reliable and efficient rotation mechanism. Hydraulic-driven drums are popular due to their smooth operation and precise speed control.

5. The engine power determines the truck's ability to carry heavy loads and operate smoothly. A powerful engine is necessary, especially for trucks with larger drum capacities.

6. Opt for well-known brands with a good reputation for quality and reliability. Brands that have been in the market for a long time usually have more experience in manufacturing and are more likely to offer better-built trucks.

Rotation Mechanism: The mixer drum is the heart of the concrete mixer truck. It rotates to mix the concrete ingredients thoroughly. Most modern trucks have a hydraulic-driven rotation system.

Blade Design: The inside of the drum is equipped with mixing blades. These blades are carefully designed to lift and tumble the concrete ingredients.

Drum Capacity: The capacity of the mixer drum varies widely. It can range from a few cubic meters to over 10 cubic meters. The drum's size is designed to meet different construction needs.

Chute Discharge: The chute-type discharge system is a traditional and widely used option. It consists of a metal chute that can be adjusted in terms of angle and length.

Conveyor - Belt Discharge: This more advanced discharge system offers greater flexibility. A conveyor-belt system can be adjusted to different heights and angles, allowing for the concrete to be poured onto elevated structures such as the upper floors of a building.

Chassis Strength: The truck's chassis is built to withstand the heavy weight of the mixer drum and the concrete it carries. It's typically made of high-strength steel, with a rigid frame structure.

Maneuverability: Concrete mixer trucks need to be able to operate in various construction site environments. They have a relatively large turning radius compared to some other vehicles, but modern designs have been improving their maneuverability.

Mixing Control: The control system allows the operator to manage the mixing process. It includes controls for the rotation speed of the mixer drum and the addition of water.