A concrete pump truck is a remarkable piece of equipment in the construction field. It combines a powerful pump with a long, articulated boom. The pump is capable of delivering concrete with high pressure, ensuring a smooth and continuous flow. The boom, which can be extended and maneuvered precisely, allows the concrete to reach distant or elevated areas on the construction site. The truck's chassis provides stability and mobility. With advanced hydraulic and control systems, it offers great flexibility in concrete placement, saving time and labor. It is an essential tool for large-scale construction projects, enhancing efficiency and precision in the pouring process.

| The specification of 28Meters Concrete Pump Truck | ||

| Cab | row half a cab, two doors, rated passengers 2 or 3, optional AC | |

| Chassis | Brand | Dongfeng |

| Drive type | 4*2 | |

| Tire | 10.00R20 with 1 spare tire | |

| Tire No. | 6+1(spare) | |

| Braking System | air brake | |

| Transmission | Manual , 8 forward and 1 reverse | |

| Engine | Engine model | YC6J180 |

| Engine brand | Yuchai | |

| fuel type | diesel | |

| Horse Power(KW/HP) | 132kw/180hp | |

| Displacement(ml) | 6500ml | |

| Emission standard | Euro3/4/5 | |

| Overall dimension (L*W*H/mm) | 10350x2500x3550mm | |

| Dimension & weight | Axles No. | 2 |

| Curb Weight(kg) | 16000 | |

| Max speed(km/h) | 90 | |

| Transport medium | concrete | |

| performance parameter | boom | 4 parts, high-strength steel material, multifold |

| Maximum Pumping conveying vertical height | 28m | |

| Radius of boom rotation | 25m | |

| Angle of boom rotary | 360 degree | |

| maximum pump output in theory | 60m3/h | |

| theoretic pumping output pressure | 9-11Mpa | |

| Concrete slump | 14-23cm | |

| Concrete conveying cylinder diameter | 200mm | |

| maximum pump frequency | 26 times/13min | |

| Pumping hydraulic system rated pressure | 30Mpa | |

| bucket volume | 500 liters | |

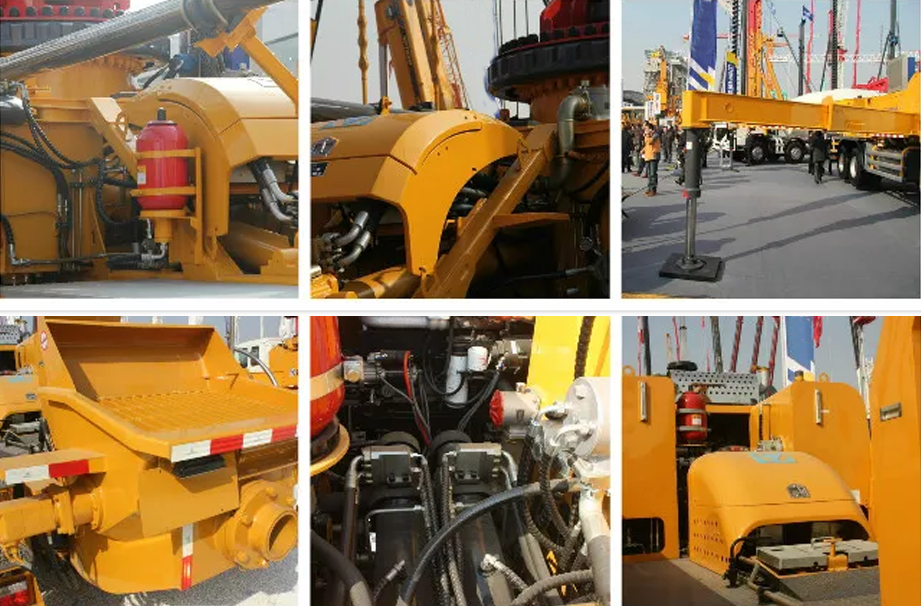

| Standard configuration | Concrete pump, stirring apparatus, separate sifter, boom, concrete spreader pole, transmission pipeline, distributing valve, power take-off device, control system, hydraulic system, electrical system, turntable, support platform and support legs, etc | |

1. The chassis of a concrete pump truck is the base structure that provides support and mobility. It's typically a heavy-duty truck chassis, designed to handle the weight of the pump, the boom, and the concrete being pumped.

2. Tandem-axle configurations are common for larger concrete pump trucks to ensure stability, especially when the boom is extended and the truck is carrying a heavy load of concrete.

3. The concrete pump is the core component responsible for moving the concrete from the hopper to the desired location through the boom. There are two main types of concrete pumps: piston pumps and squeeze pumps.

4. The boom is the most distinctive feature of a concrete pump truck. It's a long, articulated structure that can be extended and maneuvered to reach different parts of the construction site.

5. The hydraulic system is a crucial part of the concrete pump truck. It powers the movement of the boom, the operation of the pump, and other functions such as the agitators in the hopper.

6. The control system of a concrete pump truck allows the operator to manage the various functions of the vehicle. It's usually located in a control cabin, which provides a good view of the construction site and the boom's operation.

7. The outrigger system is essential for the stability of the concrete pump truck during operation. It consists of hydraulic-operated outriggers that are extended from the sides of the truck chassis.

1. Concrete Output: The pumping capacity is measured in cubic meters per hour (m³/h). For small-scale construction projects such as residential buildings or small commercial structures, a pump truck with a capacity of 30-60 m³/h might be sufficient.

2. Pressure Requirement: Consider the height and distance the concrete needs to be pumped. Taller buildings or longer horizontal pumping distances demand higher pressure.

3. Vertical and Horizontal Reach: The boom length determines the maximum height and distance the concrete can be placed. A shorter boom, around 20-30 meters, is suitable for low-rise buildings and small construction sites.

4. Boom Configuration: Some booms have multiple sections and articulation points, which provide greater flexibility in reaching difficult-to-access areas.

5. Chassis Strength: Look for a robust and durable chassis made of high-strength steel. The chassis should be able to support the weight of the pump, the boom, and the concrete without deforming.

6. Maneuverability: Consider the size and layout of the construction sites where the pump truck will be used. A truck with a good turning radius and a compact design (when the boom is folded) is easier to transport and operate in confined spaces.

7. Engine Power: A powerful engine is necessary to drive the pump and operate the boom. The engine power is usually measured in horsepower (hp).

8. Fuel Type and Efficiency: Diesel-powered engines are common due to their high torque output, which is beneficial for heavy-duty applications.

The concrete pump installed in the truck is highly efficient. It can handle a wide range of concrete viscosities and aggregates. Piston pumps are commonly used, which can generate significant pressure.

The boom is a standout feature. It is usually made of high-strength steel and can be extended and retracted telescopically. Booms can range in length from around 20 to over 60 meters.

The control system of a concrete pump truck is highly sophisticated. It allows the operator to control the pumping speed, pressure, and the movement of the boom with great precision. The controls are usually located in a well-designed cabin that offers a good view of the operation area.

The chassis is built to withstand the heavy loads and forces involved. It is made of thick, durable steel and has a strong frame structure. The axles are designed to distribute the weight evenly. To enhance stability during pumping, especially when the boom is extended, outriggers are installed.

The hydraulic system powers the pump, boom movement, and other functions. It consists of a high-power hydraulic pump, usually driven by the truck's engine. The hydraulic fluid is circulated through a network of hoses and valves to drive the pistons in the pump and the cylinders in the boom.