A cone crusher is a vital piece of equipment in the mining and aggregates industries. It features a conical mantle rotating within a concave bowl. As the mantle spins, it crushes materials by applying intense pressure and a continuous squeezing action. This crusher is highly efficient at reducing hard rocks, ores, and gravel into finer particles. With adjustable settings, operators can precisely control the output size. Its robust construction, often using manganese steel components, endures heavy-duty use. Cone crushers enhance productivity, making them indispensable for large-scale crushing operations.

| TECHNICAL DATA | |

| Feeding unit | |

| Feed capacity up to approx. (t/h) | 270 |

| Max. feed size (mm) | 200 |

| Feed height approx. (mm) | 2680 |

| Feed height with extension approx. (mm) | 3240 |

| Hopper volume (with extension) approx. (m³) | 6.6 (8.3) |

| Width x length approx. (mm) | 2,780 x 3,000 |

| Width x length with extension approx. (mm) | 3,700 x 3,500 |

| Feeding conveyor | |

| Width x length (mm) | 1,000 x 6,400 |

| Crusher | |

| Cone crusher type | KX 250 |

| Crusher system size d= (mm) | 970 |

| Crusher weight approx. (kg) | 8900 |

| Crusher drive type, approx. (kW) | direct, 185 |

| Plant performance at 0 – 32 mm approx. (t/h) | 220 |

| Plant performance at 0 – 63 mm approx. (t/h) | 270 |

| Crusher discharge conveyor | |

| Width x length (mm) | 800 x 9,100 |

| Discharge height approx. (mm) | 3300 |

| Power supply unit | |

| Drive concept | diesel-direct |

| Drive output of Scania diesel engine (kW) | 287 – 289 |

| Generator (kVA) | 135 |

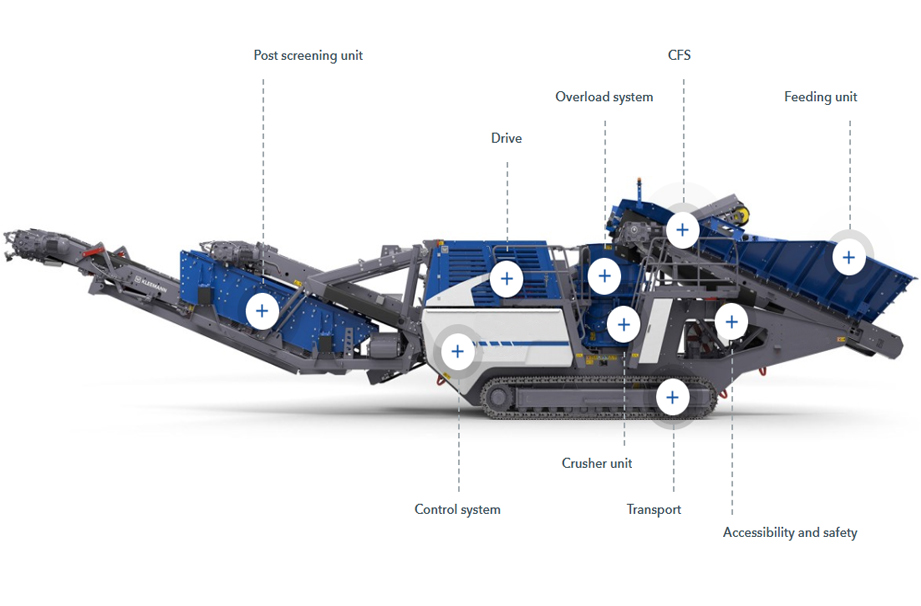

| Post screening unit (optional) | |

| Single-deck post screening unit | |

| > Width x length (mm) | 1,350 x 4,000 |

| > Return conveyor (mm) | 500 x 9,000 |

| > Discharge height of fine grain discharge conveyor approx. (mm) | 3,600 |

| Post screening unit (optional) | |

| Double-deck post screening unit | |

| > Width x length (mm) | 1,350 x 4,500 |

| > Return conveyor (mm) | 500 x 9,000 |

| > Discharge height of fine grain discharge conveyor approx. (mm) | 3,600 |

| Transport | |

| Transport dimensions without options | |

| > Transport length approx. (mm) | 16000 |

| > Transport width approx. (mm) | 3000 |

| > Transport weight of basic plant – max. configuration (kg) | 34,000 – 37,000 |

| Transport dimensions with post screening unit | |

| > Transport length with single-deck post screening unit (mm) | 20200 |

| > Transport length with double-deck post screening unit (mm) | 20700 |

| > Transport width with screening unit (mm) | 3240 |

| > Transport height with screening unit (mm) | 3400 |

| Transport weight | |

| > Transport weight single-deck post screening unit (kg) | 8930 |

| > Transport weight double-deck post screening unit (kg) | 10900 |

| > Transport weight of basic plant – max. configuration (kg) | 43,500 – 48,500 |

1. The frame of a cone crusher is a heavy-duty, rigid structure that provides support for all other components. It's usually made of cast steel, which gives it the strength to withstand the significant forces generated during the crushing process.

2. The main shaft is a crucial component that runs through the center of the crusher. It's typically made of high-strength alloy steel to bear the heavy loads and rotational forces. The upper end of the shaft is connected to the mantle, and the lower end is supported by a bearing in the frame.

3. The mantle is a conical-shaped component that rotates eccentrically within the concave bowl. These two parts are the main working elements of the cone crusher.

4. The eccentric sleeve is mounted on the main shaft and is responsible for creating the eccentric motion of the mantle. It's driven by a gear mechanism.

5. The hydraulic system in a cone crusher plays multiple important roles. It's used for adjusting the gap between the mantle and the concave, allowing operators to control the output size of the crushed material.

6. A well-designed lubrication system is essential to ensure the smooth operation of a cone crusher. The system typically includes pumps, filters, and distribution lines that supply lubricating oil to the bearings, gears, and other moving parts.

7. The drive system of a cone crusher usually consists of an electric motor and a belt-drive or gear-drive mechanism. The motor provides the power to rotate the main shaft and the mantle.

1. Consider Material Characteristics

● Hardness: When dealing with high-hardness materials such as granite and quartzite, a cone crusher with strong crushing force and excellent wear-resistance is required.

● Moisture: High-moisture materials are prone to clogging, which affects the crushing efficiency. You can choose a cone crusher with an anti-clogging design or a larger discharge port to ensure smooth material discharge.

● Particle Size: Understand the maximum particle size and particle size distribution of the feed. Ensure that the size of the crusher's feed opening and the design of the crushing chamber can adapt to the feed to avoid problems such as feed clogging or insufficient crushing.

2. Clarify Production Requirements

● Production Capacity: According to the production scale and planned output, select a cone crusher with a matching processing capacity.

● Product Particle Size Requirements: If fine-grained products such as fine aggregates for concrete mixing plants are needed, a short-head cone crusher or a model with multi-stage crushing function and precise control of the discharge particle size can be selected.

3. Pay Attention to Equipment Performance

● Crushing Chamber Type: The standard-type crushing chamber is suitable for medium-crushing, and the short-head type is suitable for fine-crushing.

● Automation Degree: A highly-automated cone crusher, such as one equipped with an automatic control system, can achieve remote monitoring, automatic adjustment of the discharge opening size, and fault diagnosis.

● Power and Efficiency: Select equipment with appropriate power. It should meet the crushing requirements and avoid energy waste.

Cone crushers have a unique crushing action. The mantle rotates eccentrically within the concave bowl, creating a continuous compressive force. This force squeezes and grinds the material between the mantle and the concave.

They are suitable for both secondary and tertiary crushing stages. In the secondary crushing stage, cone crushers can reduce the size of material from a primary crusher to a more manageable size for further processing.

Cone crushers offer the advantage of adjustable settings. The gap between the mantle and the concave can be adjusted to control the output size of the crushed material. This adjustment can be made through hydraulic or mechanical means.

These crushers are designed to handle a significant volume of material. They have a large feed opening that allows for the efficient feeding of relatively large chunks of material.

The construction of cone crushers is characterized by robustness and durability. The frame is usually made of heavy - duty cast steel, providing a stable base to support the crushing components.

Many modern cone crushers are equipped with advanced protection and control systems. The hydraulic tramp-release system is a key feature.