Forklift loaders are indispensable machines in warehouses, factories, and logistics centers. They feature a sturdy mast and a set of forks attached to a movable carriage. These forks can be raised, lowered, and tilted hydraulically, allowing for precise handling of palletized loads. Powered by a reliable engine or electric motor, they offer sufficient power to lift heavy weights. The operator's cab is designed for comfort, with good visibility and ergonomic controls. Whether it's loading and unloading trucks, stacking goods in storage racks, or transporting materials within a facility, forklift loaders enhance efficiency and productivity, ensuring the smooth flow of goods.

| Item | Content | Unit | Description |

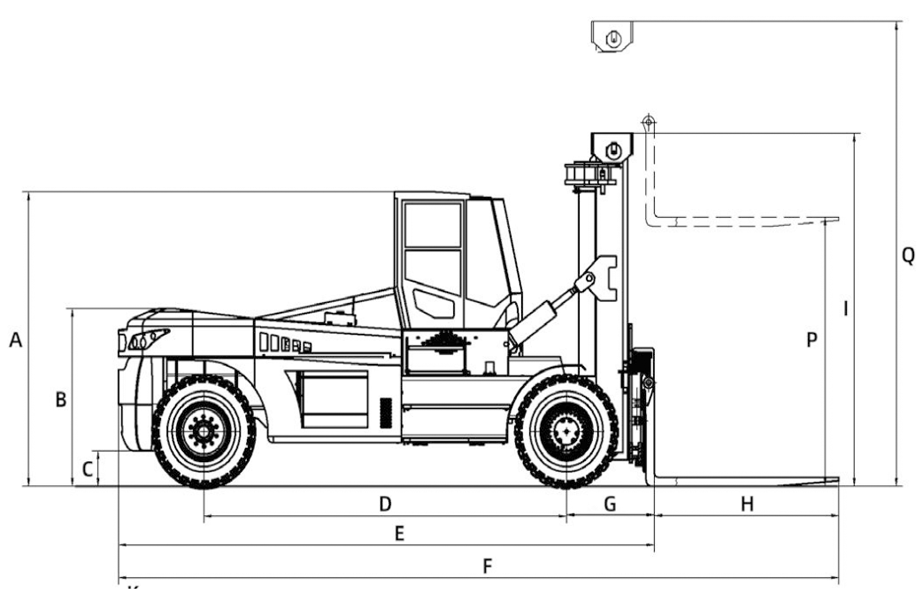

| Features | Rated Load | Q(t) | 25 |

| Load center | c(mm) | 1250 | |

| Wheelbase | D(mm) | 4400 | |

| Weight | Weight | kg | 35000 |

| Chassis | Tyre Specs.:Front | - | 14.00-24-28PR |

| Tyre Specs.:Rear | - | 14.00-24-28PR | |

| Tyres Qty,front/rear(X-drive wheels) | - | 4\2 | |

| Wheel tread: Front | (mm) | 2200 | |

| Wheel tread:Rear | (mm) | 2390 | |

| Dimension | Mast/carriage tilt angle(front/rear) | Degree (° ) | 6\12 |

| Mast height(fork lowering) | I(mm) | 3860 | |

| Mast lifting height | P(mm) | 3500 | |

| Max.lifting height | Q(mm) | 5610 | |

| Height to head guard(height to cab) | A(mm) | 3510 | |

| Overall length(without forks) | E(mm) | 6745 | |

| Overall width | L(mm) | 3050 | |

| Fork dimension | H/M(mm) | 2440X300X110 | |

| Mast min ground dearance(with load) | G(mm) | 300 | |

| Wheelbase center min ground clearance | C (mm) | 420 | |

| Min.Turning radius | K(mm) | 6700 | |

| Travel speed(loaded/unloaded) | km/h | 25/29 | |

| Performance | Max.lifting speed(loaded/unloaded) | mm/s | 260/270 |

| Max. Lowering speed(loaded/unloaded) | mm/s | 315/260 | |

| Traction | kN | 170 | |

| Gradeablity(loaded/unloaded) | % | 20/21 | |

| Driving brake | - | ||

| Engine | Engine | - | Yuchai engine |

| Model | - | YCK09220-T401 | |

| Rated output/ Speed | kW/rpm | 162/2200 | |

| Engine | - | GX Cummins | |

| Model | - | QSL9.3-C220 | |

| Rated output/ Speed | kW/rpm | 165/2200 | |

| Engine | - | Cummins | |

| Model | - | B6.7 FR96072 | |

| Rated output/ Speed | kW/rpm | ||

| Cylinder No. | L | 6 | |

| Others | Transmission gears(Front/rear) | 2\1 | |

| Attachments working pressure | MPa | 18 | |

| Attachments using oil amount | L/min | 80 |

1. The chassis of a forklift loader is the main structural support. It's typically a heavy-duty, welded-steel structure that provides stability and strength. The frame is designed to withstand the forces exerted during lifting and transporting operations.

2. Mast: The mast is the vertical structure that allows the forks to be raised and lowered. It's usually made of high-strength steel and consists of multiple sections that can telescope or slide relative to each other.

3. Carriage: The carriage is attached to the mast and holds the forks. It can also move horizontally along the length of the forks to adjust the load's position.

4. The forks are the key components for handling palletized loads. They are long, tapered metal prongs that slide into the openings of pallets.

5. Hydraulic Pump: The heart of the hydraulic system, the pump pressurizes the hydraulic fluid.

6. Hydraulic Cylinders: These cylinders convert the hydraulic pressure into mechanical force. They control the motion of the mast (raising and lowering), the carriage (tilting and side-shifting), and the forks (if there's any fork-related movement).

7. Hoses and Valves: High-quality hoses carry the hydraulic fluid between components, while valves regulate the flow and direction of the fluid.

8. Engine - Powered Forklifts: These forklifts are equipped with an internal combustion engine, usually a diesel or gasoline engine. The engine provides the power to drive the hydraulic pump, move the wheels, and operate other functions.

1. Load Capacity: Determine the heaviest weight you need to lift. Forklift load capacities range from a few thousand pounds to over 50,000 pounds.

2. Load Dimensions: Think about the size of the loads you'll handle. The length, width, and height of the forks and the carriage should be suitable for your pallets or other items.

3. Lift Height: Measure the height to which you need to lift and store your goods. This could be the height of storage racks in a warehouse.

4. Mast Type: Consider the type of mast based on your lifting requirements. Some masts offer better visibility during operation, while others provide more stability.

5. Indoor vs. Outdoor: For indoor use, such as in a warehouse, an electric forklift is often a better choice due to its quiet operation and lack of emissions.

6. Terrain and Floor Conditions: If you're working on uneven or rough terrains, a forklift with pneumatic tires and a more robust chassis is preferable.

7. Engine-Powered: Engine-powered forklifts are more suitable for heavy - duty applications and environments where refueling is more convenient than recharging.

8. Electric: Electric forklifts are energy-efficient, quiet, and produce zero emissions. They are ideal for indoor use and for operations where noise is a concern.

Forklift loaders are equipped with a robust mast and carriage system. The mast, which can be two-stage or three-stage, enables the forks to be raised to significant heights.

The forks at the front of the forklift are designed for precise handling of palletized loads. They can slide into the openings of pallets with accuracy, and the carriage holding the forks can be tilted forward and backward.

Forklift loaders can handle a wide variety of load types and sizes. The forks can be adjusted in width to accommodate different pallet dimensions.

These machines are designed to operate in relatively tight spaces such as warehouse aisles. They have a compact design and a relatively small turning radius, often with the ability to pivot or make sharp turns.

The operator's cab of a forklift loader is designed with the operator's comfort and functionality in mind. It provides a clear view of the forks and the work area through large windows and well-placed mirrors.

Forklift loaders can be powered by different sources. Engine-powered forklifts, typically using diesel or gasoline engines, offer high power output and are suitable for outdoor and heavy-duty applications.