Harvesters are essential machines in modern agriculture. They are engineered to efficiently gather crops like grains, wheat, and corn. With a robust metal frame, they can withstand the rigors of the field. The cutting mechanism, often a sharp reel or header, slices through the standing crop. A conveyor system then transports the harvested material to a storage bin. Powered by high-performance engines, they move steadily across the land. The operator's cab offers comfort and good visibility, allowing for precise control. Harvesters significantly boost productivity, saving farmers valuable time and labor.

| Horsepower | Cumis 240HP | |

| Drive type | 2WD | |

| Dimension(L*W*H)(mm ) | 7120*2930*3400 | |

| Weight(kg) | 9120 | |

| Header | Number of rows | 4 |

| Row distance(mm) | 600 | |

| Available row distance(mm) | 550-650 | |

| Working width(mm) | 2550 | |

| Header type | Roller type | |

| Peeling roller Qty(unit) | 5 | |

| Production efficiency | Productivity(hm²/h) | 0.4-0.7 |

| Fuel consumption(L/hm²) | ≤47 | |

| Fuel tank capacity(L) | 280 | |

| Mini clearance(mm) | 260 | |

| Thresher | Grain tank(m³) | 2.8 |

| Max unload height(mm) | 2800 | |

| Straw returning width(mm) | 2300 | |

| Chassis | Wheel base(mm) | 3020 |

| F/R wheel space(mm) | F:1950/R:1750 | |

| Tyre model(F/R) | F:15R24/ | |

| R:400/60-15.5 | ||

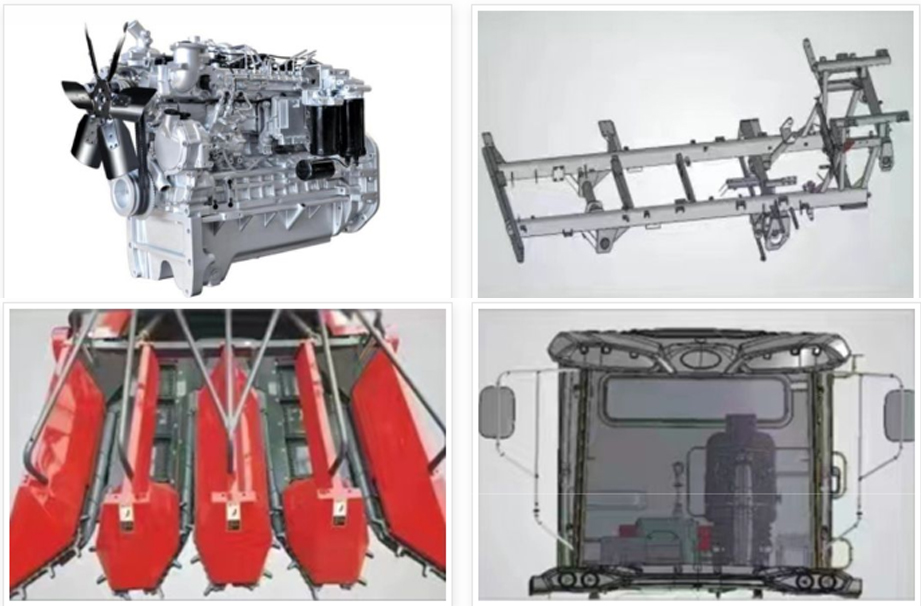

1. The frame of a harvester is the main structural support. It's typically made of heavy-duty steel to provide the strength and rigidity needed to withstand the forces during operation.

2. Header or Reel: The header is the part that cuts the standing crops. For cereal crops like wheat and barley, a combine harvester usually has a wide, flat-bottomed header.

3. Cutter Bar: The cutter bar is a crucial part of the cutting unit. It's a long, thin bar with a series of reciprocating or rotating blades. The blades move back and forth or rotate at high speed to cut the crop.

4. Auger or Belt Conveyor: After the crop is cut, it's transferred to the harvester's body through a conveyor system. An auger conveyor, which is a large screw-like device, is often used to move the cut crop sideways.

5. Feeding Mechanism: The feeding mechanism is responsible for guiding the cut crop into the threshing unit. It usually consists of a set of rollers or chains that grip the crop and pull it into the threshing drum.

6. Threshing Drum: The threshing drum is the heart of the threshing process. It rotates at high speed and uses a combination of impact and friction to separate the grains from the straw and chaff.

7. Separating Grates and Screens: After threshing, the mixture of grains, straw, and chaff passes through a series of separating grates and screens.

8. Grain Elevator: The grain elevator is a vertical conveyor that lifts the grains from the separating unit to the grain tank. It usually consists of a belt with cups or buckets that carry the grains upward.

9. Grain Tank: The grain tank is a large storage container located on the harvester. Its size varies depending on the model and the intended use of the harvester.

10. Engine: Harvesters are powered by internal combustion engines, usually diesel engines. The engine provides the necessary power to drive the cutting unit, conveyor systems, threshing drum, and the wheels or tracks that move the harvester forward.

1. Crop Type:Different crops require specific harvesters. For example, combine harvesters are suitable for cereal crops like wheat, rice, and corn.

2. Field Size and Shape:Larger fields are better served by larger, more efficient harvesters with wider cutting widths and higher capacities to reduce the time spent on harvesting.

3. Terrain and Field Conditions:For hilly or uneven terrains, tracked harvesters offer better stability and traction.

4. Cutting Width:A wider cutting width means more area can be harvested in one pass, increasing productivity.

5. Threshing and Separating Efficiency:Efficient threshing and separating mechanisms are crucial to ensure minimal grain loss and high-quality separation of grains from straw and chaff.

6. Power and Fuel Efficiency:The power of the harvester's engine should be sufficient to handle the workload.

7. Operating Speed:A harvester that can operate at a reasonable speed without sacrificing the quality of the harvest is ideal.

8. Operator Comfort and Ergonomics:A comfortable operator's cab with good visibility, easy-to-reach controls, and a smooth ride can reduce operator fatigue and increase productivity.

9. Maintenance Requirements:Choose a harvester that is easy to maintain, with accessible components for routine checks and repairs.

10. Safety Features:Safety should be a top priority. Look for harvesters equipped with safety guards, emergency stop buttons, stable platforms, and other safety features to protect the operator and prevent accidents.

The cutting unit of a harvester is designed for precision and productivity. The header, often adjustable in height, is equipped with a reel and a cutter bar. The reel guides the crop towards the cutter bar, which contains sharp blades.

After cutting, an efficient conveyor system transports the harvested crop. Auger or belt conveyors move the cut material smoothly from the cutting unit to the threshing and separating components.

The threshing drum is a central feature. It rotates at high speed and uses a combination of impact and friction to separate grains from the straw and chaff. The drum is usually covered with rasp bars or teeth that beat the crop as it passes through.

A well-designed grain elevator lifts the separated grains from the separating unit to the grain tank. The grain tank has a sufficient capacity to hold the harvested grains before unloading. Some modern harvesters have grain tanks that can hold thousands of liters of grains.

Harvesters are powered by robust engines, typically diesel-powered. The engine provides the necessary horsepower and torque to drive the cutting unit, conveyor systems, threshing drum, and the wheels or tracks for movement.

The operator's cab is designed with comfort and functionality in mind. It provides excellent visibility of the harvesting process, allowing the operator to monitor the cutting, conveying, and threshing operations.