Log loaders are specialized heavy machines designed for the forestry industry. They feature a powerful grapple or claw attachment at the front, capable of firmly gripping and lifting large logs. The long boom provides an extended reach, allowing operators to access logs in various positions, whether they're on the ground or piled up. These machines are typically built with a sturdy chassis and high ground clearance to navigate rough forest terrains. Powered by robust engines, they offer the strength needed to handle heavy loads. The operator's cab is ergonomically designed, ensuring comfort and clear visibility, which is vital for safe and efficient log handling operations.

| Description | Unit | Parameter value | |

| Rated working load | kg | 6000 | |

| Bucket capacity | m3 | 3.5 | |

| Operating weight | kg | 20000±300 | |

| Traveling speed in various gears | Forward I/II/III/IV Gear | km/h | 6/11/20/34 |

| Reverse I/II/III/IV gear | km/h | 6/11/20/34 | |

| Maximum grade ability | ° | 28 | |

| Highest Unloading Position | Unloading angel | ° | 43 |

| Unloading height | mm | 3170 | |

| Unloadingdistance | mm | 1200 | |

| Bucket digging force | kN | 205 | |

| Maximum digging depth | mm | 82 | |

| Boom lifting time | s | ≤5.9 | |

| Total cycling time | s | ≤10.9 | |

| Minimum turning radius | Outside of bucket | mm | 7100 |

| Tire center | mm | 6005 | |

| Machine steering angle | ° | ±38 | |

| Tire specification | 23.5-25 | ||

| Tire inflation pressure | Front wheel | MPa | 0.44~0.46 |

| Rear wheel | MPa | 0.38~0.40 | |

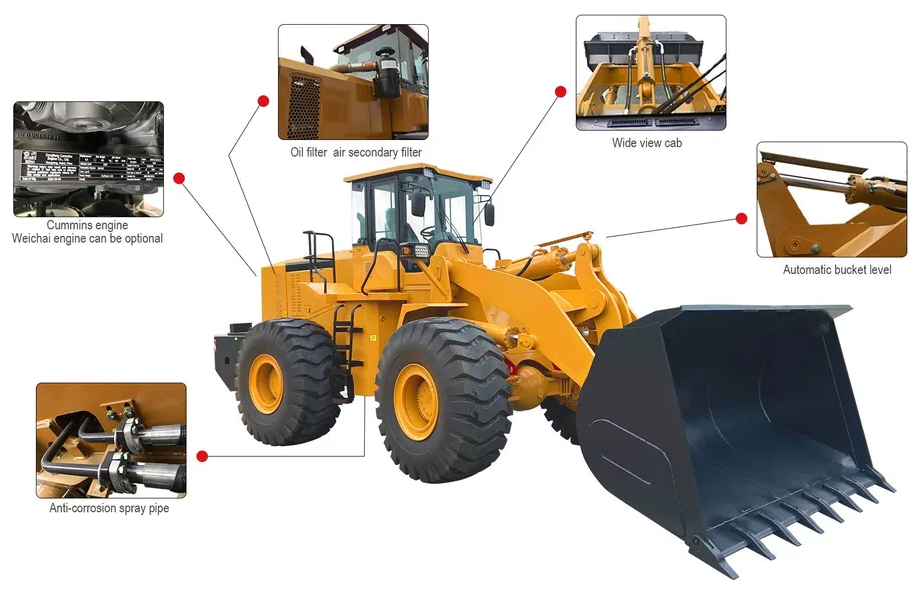

1. Structure and Material: The chassis is a rugged, heavy-duty welded steel structure. It provides a stable foundation and strong support for the entire machine, usually made of high-strength steel to withstand the enormous pressure and weight during operation.

2. Functional Features: It is designed with a high ground clearance to facilitate movement over rough, muddy, or rocky forest terrains, preventing the machine from getting stuck.

3. Types and Construction: Booms come in telescopic and articulated types. Telescopic booms, made of high-strength steel, can extend and retract through an internal hydraulic system, providing a long working range.

4. Movement and Control: The extension, lifting, and articulation (if applicable) of the boom are driven by hydraulic cylinders.

5. Types and Design: The grapple is a crucial working part of the log loader. Common ones include claw-type grapples and clamp-type grapples.

6. Operation and Function: The opening, closing, and rotation of the grapple are controlled by hydraulic cylinders.

7. Hydraulic Pump: As the core power source of the hydraulic system, it is usually driven by the engine and is responsible for pressurizing the hydraulic fluid to provide sufficient pressure for the movement of components such as the boom and grapple.

8. Engine: Generally, a diesel engine is adopted because of its high-torque output characteristics, which can provide powerful power for the log loader to meet the requirements of lifting and transporting heavy objects.

1. Determine the maximum size and weight of the logs you'll typically handle. Log loaders have different load capacities, so make sure the loader you choose can handle the heaviest and largest logs you expect to encounter.

2. Assess the reach you need to access logs in various positions. If your work area has deep log piles or logs located at a distance from the loader's base position, a longer boom or better reach is essential.

3. Consider the type of forest terrain where the log loader will be used. For rough, mountainous, or swampy areas, a loader with excellent ground clearance, large, durable tires, or tracks is crucial.

4. If you operate in areas with extreme weather, such as heavy rain or snow, look for a log loader with features that can handle these conditions.

5. A powerful engine is essential for lifting and moving heavy logs. Look for a log loader with sufficient horsepower and torque to handle your workload.

6. The hydraulic system powers the movement of the boom and grapple. A high-quality hydraulic system with a strong pump, durable cylinders, and reliable hoses and valves is crucial.

7. Different grapple designs are better suited for different types of logs. For example, a claw-shaped grapple might be more effective for rough-barked logs, while a clamp-shaped grapple could be better for smooth-barked or irregular-shaped logs.

Log loaders are designed with a strong grapple attachment that can firmly grip logs of various sizes and shapes. The grapple's force and grip are optimized to handle heavy logs, allowing for efficient loading and unloading.

The boom of a log loader provides an extended reach, which is crucial for accessing logs in different positions. Telescopic or articulated booms can reach over piles of logs, into ditches, or across other obstacles to pick up logs.

Built to withstand the harsh conditions of forestry work, log loaders have a heavy-duty frame and components. The chassis is designed to handle rough terrains, with features like high ground clearance and durable tires or tracks.

A powerful hydraulic system is at the heart of a log loader's operation. It powers the movement of the boom and the grapple, providing the force needed to lift, rotate, and position logs precisely.

The operator's cab is designed for comfort and functionality. It offers excellent visibility of the work area through large windows and well-placed mirrors, allowing the operator to see the log-handling process clearly.