Mining trucks are heavy-duty behemoths purpose-built for the mining industry. These trucks feature an enormous hauling capacity, capable of transporting vast quantities of ore, coal, or other minerals from the mine site to processing areas. With their robust frames and suspensions, they can endure the punishing terrains and heavy loads. The powerful diesel engines generate the immense torque needed to ascend steep slopes and haul hefty payloads. The cabins are designed for operator comfort, providing excellent visibility and ergonomic controls. Their large, rugged tires offer stability and traction, making them indispensable tools for efficient and safe mining operations.

| Pictures |

|

|

|

|

|

| General parameters | |||||

| Model | 773E | 777D | 777G(Tier 2) | 785C | 793D |

| Engine | |||||

| Model | Cat® 3412E | Cat® 3508B EUI | Cat® C32 ACERT™ | Cat® 3512B-EUI | Cat 3516B HD EUI |

| Rotational speed (rpm) | 2000 | 1750 | 1750 | ||

| Flywheel power (kW) | 501 | 699 | 704 | 1005 | 1743 |

| Cylinder Bore (mm) | 137 | 170 | 146 | 170 | 170 |

| Stroke (mm) | 152 | 190 | 162 | 190 | 215 |

| Displacement (L) | 27 | 34.5 | 32.1 | 51.8 | 78 |

| Number of cylinders (pcs) | 12 | 12 | |||

| Performance | |||||

| Rated load capacity (kg) | 55500 | 90400 | 100000 | 136000 | 218000 |

| Maximum load speed (km/h) | 62.2 | 60.4 | 65.9 | 55 | 54.3 |

| Unladen weight (kg) | 43800 | 72960 | 64654 | 102150 (flat base plate)/95725 (double bevel) | 165749 |

| Full load mass (kg) | 99300 | 163360 | 164654 | 249480 | 383749 |

| Loading capacity (m³) | 26.6 | 60.1 | 41.9 | 78 | 129 |

| Maximum unloading height (mm) | 676 | 10059 | 1284 | 1364 | |

| Minimum Turning Radius (mm) | 12500 | 14200 | 14200 | 13750 | |

| Maximum travel speed (km/h) | 62.2 | 60.4 | |||

| Carriage lift time (s) | 9.5 | 15 | 15 | 15.2 | 20.3 |

| Car landing time (s) | 12.5 | 13 | 13 | 15.9 | 17.5 |

| Traveling speed | |||||

| Travel speed 1st gear (forward) (km/h) | 9.9 | 10.5 | 10.9 | 12.1 | 11.8 |

| Travel speed 2nd gear (forward) (km/h) | 13.9 | 14.3 | 14.8 | 16.3 | 15.9 |

| Travel speed 3rd gear (forward) (km/h) | 18.8 | 19.3 | 20.1 | 22.2 | 21.5 |

| Travel speed 4th gear (forward) (km/h) | 25.2 | 26 | 27.2 | 29.9 | 29 |

| Travel speed 5th gear (forward) (km/h) | 34.1 | 34.9 | 36.9 | 40.6 | 39.4 |

| Travel speed 6th gear (forward) (km/h) | 45.9 | 46.6 | 49.4 | 54.8 | 54.3 |

| Travel speed 7th gear (forward) (km/h) | 62.2 | 60.4 | 67.1 | ||

| Travel speed (backward) (km/h) | 13.1 | 11.9 | 12.4 | 11 | 10.9 |

| Speed ratio | 17.48:1 | 19.16:1 | 19.1576:1 | 22.75:1 | 28.8:1 |

| Tires | |||||

| Tire Specification | 24.00-R35 (E4) | 27.00R49 (E4) Tire | 27.00R49 (E4) | 33.00-R51 (E4) 33.00-R51 (E3) | 40.00R57 |

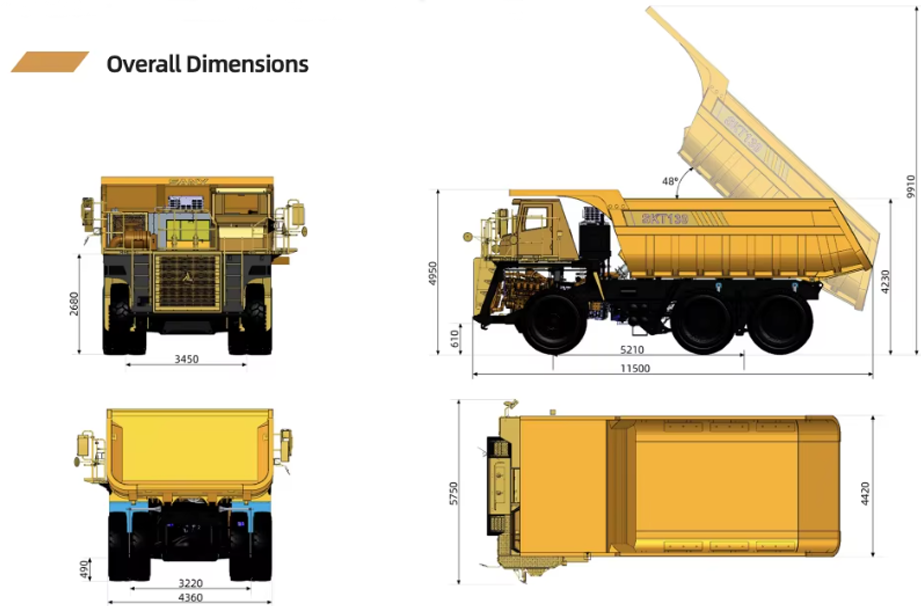

| Dimension | |||||

| Overall length (mm) | 9120 | 9780 | 10535 | 11024 | 12862 |

| Overall width (mm) | 5076 | 6105 | 6687 | 6640 | 7680 |

| Overall height (mm) | 4393 | 5147 | 5200 | 5769 | 6494 |

| Wheelbase (mm) | 4191 | 4570 | 4560 | 5182 | 5905 |

| Minimum Ground Clearance for Dump Bucket (mm) | 566 | 1062 | 965 | 1284 | 1364 |

| Unloaded height (mm) | 3773 | 4380 | 4380 | 4968 | 5871 |

| Maximum depth inside the compartment (mm) | 1805 | 1898 | 1895 | 2132 | 2330 |

| Total height of carriage lift (mm) | 8787 | 10059 | 9953 | 11207 | 13113 |

| Maximum length of interior compartment (mm) | 6400 | 7234 | 6580 | 7652 | 9677 |

| Maximum width of interior compartment (mm) | 3658 | 5200 | 5200 | 5510 | 6500 |

| Fuel capacity | |||||

| Fuel tank capacity (L) | 700 | 1137 | 1136 | 1893 | 4354 |

| Cooling System Capacity (L) | 122 | 268 | 228 | 379 | 973 |

| Differential Capacity (L) | 155 | 306 | 227 | 248 | 189 |

| Lifting unit hydraulic oil tank (L) | 133 | 250 | 444 | 337 | 769 |

1. Structure and Material: The chassis of a mining truck is a massive, heavy-duty structure. It's usually made of high-strength steel to withstand the extreme loads and stresses. The frame is designed to evenly distribute the weight of the payload and the truck itself.

2. Adaptation to Loads: Mining trucks are designed to carry heavy payloads. The frame and chassis have features like reinforced cross-members and thick-walled structures to support the weight of the ore or minerals.

3. Capacity and Design: The cargo body is a large, open-topped container designed to hold the mined materials. It has a significant capacity, ranging from tens to hundreds of tons, depending on the size of the truck.

4. Material and Durability: Made of high-strength, wear-resistant materials such as hardened steel, the cargo body can endure the abrasion caused by the rough-edged minerals and the impact of loading equipment.

5. Type and Function: Mining trucks typically have a heavy-duty suspension system to provide a smooth ride and maintain stability. The suspension can be a combination of leaf springs, air springs, or hydraulic cylinders.

6. Adjustability: Some advanced mining truck suspensions are adjustable to adapt to different load conditions. The stiffness of the suspension can be modified to ensure optimal performance whether the truck is empty or fully loaded.

7. Tire Characteristics: The tires of mining trucks are massive and designed to handle the heavy loads and rough terrains. They have a thick tread pattern to provide excellent traction in muddy, rocky, or sandy mine conditions.

8. Wheel Design: The wheels are usually made of forged or cast steel to support the weight of the truck and the load. They have a strong hub and rim design to ensure proper mounting of the tires and to handle the torque and forces generated during operation.

1. Determine Your Requirements: Calculate the average amount of material you need to transport per trip. Consider the size and scale of your mining operation.

2. Future Expansion: Anticipate any potential growth or changes in your mining operations. If you plan to increase production in the future, it might be wise to invest in a truck with a slightly higher payload capacity than your current needs to avoid having to replace the trucks too soon.

3. Terrain Type: Analyze the terrain of your mine site. If it's a mountainous area with steep slopes, you need a truck with excellent climbing ability and stability.

4. Haul Road Quality: Consider the condition of the haul roads. If the roads are rough, rocky, or muddy, you'll require trucks with durable tires, a robust suspension, and a strong chassis.

5. Power Requirements: Mining trucks need to have sufficient engine power to carry heavy payloads and traverse difficult terrains. Look for engines with high horsepower and torque output.

6. Fuel Efficiency: Given the high volume of work and the cost of fuel in mining operations, fuel efficiency is an important factor.

7. Body Capacity and Shape: The dump body should have an appropriate capacity to match the truck's payload rating.

8. Durability: The dump body needs to be durable enough to withstand the abrasion from the mined materials.

Mining trucks are renowned for their substantial payload capacities. They can carry vast amounts of mined materials such as ore, coal, and gravel. Capacities can range from tens to hundreds of tons per load.

These trucks are equipped with robust diesel engines that generate high torque and horsepower. The powerful propulsion system allows them to climb steep inclines and move heavy loads at a reasonable speed even in the challenging terrains of mines.

The frame and body of mining trucks are built to withstand the extreme conditions of mining operations. The chassis is made of high-strength steel to support the heavy payloads and endure the shocks and vibrations from rough terrains.

A heavy-duty suspension system is a key feature of mining trucks. It helps to absorb the impacts of uneven ground surfaces and provides a smoother ride, which is crucial for both the operator's comfort and the truck's component longevity.

The operator's cab is designed with comfort and functionality in mind. It is usually elevated to provide a good view of the work area, allowing the operator to have clear visibility during loading, unloading, and transportation.

Mining trucks have an efficient dump body design and mechanism for unloading materials. The dump body can be tilted at a significant angle to ensure complete and rapid unloading of the payload.