A wheel loader is a powerful and versatile heavy machinery used widely in construction, mining, and logistics fields. It features a large, robust bucket at the front, which can scoop up and transport various materials like sand, gravel, and dirt. Mounted on four wheels, it offers good mobility and can operate on relatively smooth terrains. The operator's cab provides a comfortable working environment with excellent visibility. Powered by a high-performance diesel engine, it delivers ample strength to lift heavy loads. Wheel loaders enhance productivity, making them an essential asset for large-scale projects.

| Pictures |  |  |  |  |  |  |  |  |  |

| General parameters | |||||||||

| Model | SEM636F | SEM653F | SEM656F | SEM655F | SEM658F | SEM658F | 665F | 668F | 676F |

| Rated load capacity (kg) | 3000 | 5000 | 5000 | 5000 | 5500 | 5500 | 6000 | 6500 | 7000 |

| Operating weight (kg) | 9700 | 16500 | 17000 | 16360 | 17600 | 17200 | 20020 | 20480 | 23230 |

| Bucket capacity (m³) | 1.4~3.6 | 2.7~4.5 | 2.7~4.5 | 2.7~4.5 | 3.5(2.6~5.0) | 2.7~5 | 2.8~5.5 | 2.8~5.5 | 3.5~6.5 |

| Travel model | Tire-type | Tire-type | Tire-type | Tire-type | Tire-type | Tire-type | Tire-type | Tire-type | Tire-type |

| Application | General purpose | General purpose | General purpose | General purpose | General purpose | General purpose | General purpose | General purpose | General purpose |

| Tonnage range | 3-4 tons | 4-5 tons | 4-5 tons | 4-5 tons | 5-8 tons | 5-8 tons | 5-8 tons | 5-8 tons | 5-8 tons |

| Power Type | Fuel | Fuel | Fuel | Fuel | Fuel | Fuel | Fuel | Fuel | Fuel |

| Engine (fuel) | |||||||||

| Model | WP4.6NG125E473 | WP10G220E343 | WP10HG220E475 | WP10HG220E475 | WP10HG220E475 | WDEC WP10HG240 | WDEC WP10HG240 | WDEC WP10HG270 | |

| Rated power/speed (kW/r/min) | 92 | 162/2000 | 162 | 162 | 162 | 178 | 178 | 199 | |

| Total Displacement (L) | 4.58 | 9.7 | 9.5 | 9.5 | 9.5 | 9.5 | 9.5 | 9.5 | |

| Engine Brands | Weichai | Weichai | Weichai | Weichai | Weichai | ||||

| Emission standard | Euro 4 | Euro 4 | Euro 4 | Euro 4 | Euro 4 | Euro 4 | Euro 4 | Euro 4 | |

| Hydraulic system | |||||||||

| Rated working pressure (Mpa) | 18 | 17 | 17 | 17 | 18 | 18 | 20 | 24 | |

| Transmission | |||||||||

| Transmission Model | TR100 Fixed Shaft Gearbox | Fixed Shaft Gearbox Tr200 | TR200 Fixed Shaft Gearbox | TR200 Fixed Shaft Gearbox | Electrically controlled fixed-axis | TR200 Fixed Shaft Gearbox | SEM TR200-EH | SEM TR220-EH | SEM TR240 EH |

| Travel speed 1st gear (forward/reverse) (km/h) | 7.5/9.4 | 7.9/7.9 | 7.9 | 7.9 | 11.8/11.8 | 7.9 | 7.6/7.6 | 10/13.6 | 7.1/7.1 |

| Travel speed 2nd gear (forward/reverse) (km/h) | 13.5/29 | 15/15 | 15 | 15 | 35/35 | 15 | 15/15 | 38 | 12.7/12.7 |

| Travel speed 3rd gear (forward/reverse) (km/h) | 24 | 23/23 | 23 | 23 | 23 | 23/23 | 23.8/23.8 | ||

| Travel speed 4 speeds (forward/reverse) (km/h) | 39 | 40/40 | 39 | 39 | 39 | 39/39 | 39/39 | ||

| Dimension | |||||||||

| Overall length (mm) | 8210 | 8616 | |||||||

| Overall width (mm) | 2963 | 3200 | |||||||

| Overall height (mm) | 3350 | 3465 | |||||||

| Wheelbase (mm) | 2850 | 3200 | 3350 | 3200 | 3300 | 3350 | 3400 | 3,400 | 3550 |

| Unloading height - unloading angle of 45° (mm) | 3000 | 3100 | 3100 | 3100 | 3111 | 3100 | 3100 | 3100 | 3200 |

| Steering angle (°) | 36±1 | 35±1 | 38±1 | 35±1 | 38 | 38±1 | 38±1 | 38±1 | 35±1 |

| Boom lifting time (s) | 4.6 | 4.92 | 5.1 | 4.9 | 5.1 | 5.3 | 5.3 | 5.7 | |

| Trinomial sum time (s) | 8.1 | 8.8 | 9.3 | 8.8 | 9.6 | 9.3 | 9.7 | 9.8 | 9.8 |

| Steering system | |||||||||

| Model | Quantitative Load Sensitive Steering | Load-sensitive priority steering | Quantitative Load Sensitive Steering | Load-sensitive priority steering | Variable Load Sensitive Steering | Quantitative Load Sensitive Steering | Coaxial flow amplification | Fully hydraulic steering | |

| System working pressure (Mpa) | 14 | 16 | 16 | 16 | 16 | 18 | 18 | 20 | |

| Braking system | |||||||||

| Driving brake form | Air Top Oil Caliper Disc Brake | Air Top Oil Caliper Disc Brake | Air Top Oil Caliper Disc Brake | Air Top Oil Caliper Disc Brake | Air Top Oil Caliper Disc Brake | Air Top Oil Caliper Disc Brake | Air Top Oil Caliper Disc Brake | ||

| Parking Brake Type | Inside rising shoe drum brake | Inside rising shoe drum brake | Inside rising shoe drum brake | Inside rising shoe drum brake | Inside rising shoe drum brake | Inside rising shoe drum brake | Inside rising shoe drum brake |

1. Frame: It's the structural backbone, made of high-strength steel, providing support for components like the engine, transmission, and axles, ensuring stability and durability.

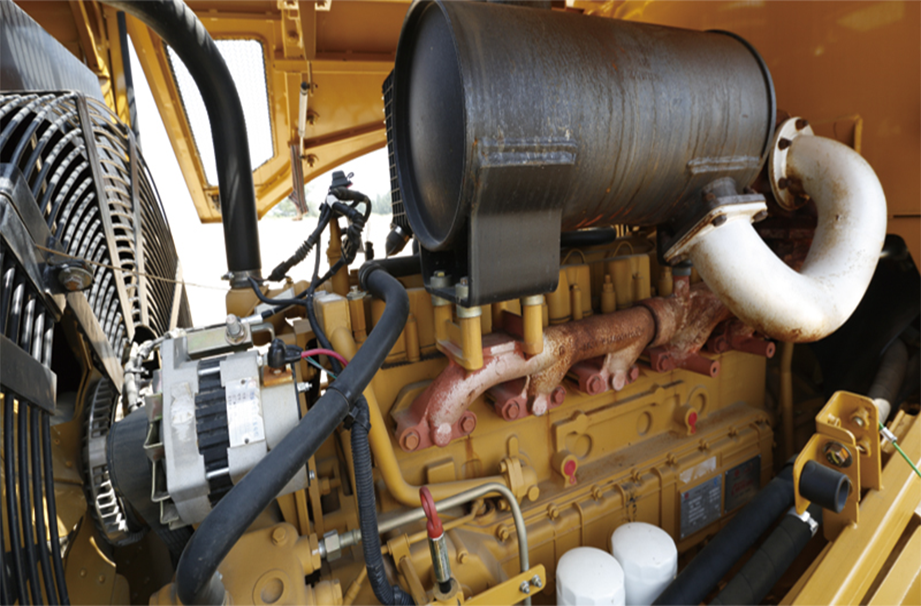

2. Engine: Usually a diesel engine, the heart of the wheel loader, generating power for driving the machine and operating hydraulic functions.

3. Transmission: Transfers power from the engine to the wheels, with powershift transmissions common for smooth gear shifting under heavy loads.

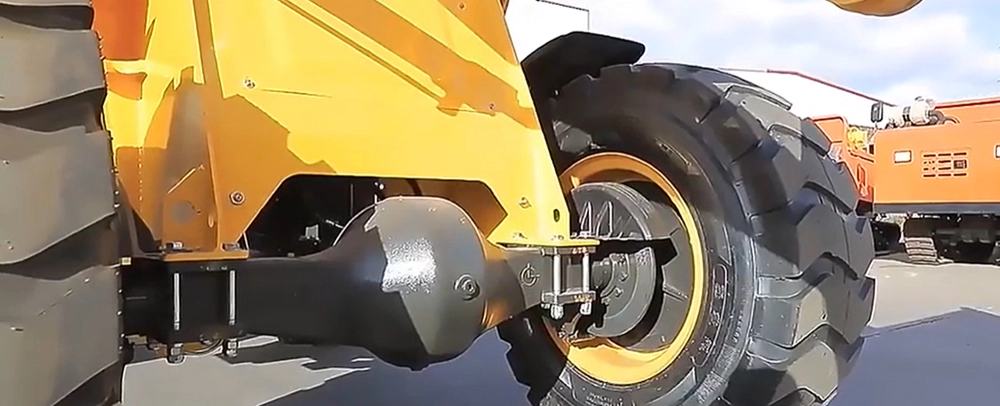

4. Axles and Tires: Heavy-duty axles transfer power to wheels, providing stability and maneuverability. Tires are large and durable, designed for heavy loads and various terrains.

5. Bucket and Loader Arms: The bucket at the front handles material loading and comes in different types. Loader arms support the bucket and are hydraulically controlled for lifting, lowering, and other operations.

6. Hydraulic System: Comprising pumps, valves, cylinders, and hoses, it powers bucket and loader arm movements and other functions.

7. Operator's Cab and Controls: The cab offers a comfortable and safe workspace with ergonomic controls, adjustable seats, and good visibility.

1. Operating Capacity: Determine the required payload capacity based on the type of materials you'll be handling and the volume of work.

2. Bucket Size: The size of the bucket should match the operating capacity and the nature of the materials. A larger bucket can move more material in one cycle but may require more power to lift and maneuver.

3. Engine Power: A powerful engine is essential for efficient operation. Diesel engines are the most common due to their high torque output.

4. Transmission: Look for a reliable transmission system. Powershift transmissions are popular as they allow for smooth and quick gear changes without the need to stop the machine.

5. Turning Radius: A small turning radius is crucial for working in confined spaces such as construction sites with many obstacles or in storage yards.

6. Travel Speed: Consider the maximum travel speed of the loader, especially if it needs to cover long distances between work areas.

7. Tire Type and Traction: The type of tires affects the loader's performance on different terrains.

8. Lifting and Tilting Capacity: The hydraulic system determines the loader's ability to lift and tilt the bucket.

9. Hydraulic Response and Control: The responsiveness of the hydraulic system is important for efficient operation.

10. Operator's Cab: A well - designed cab provides a comfortable working environment. Features such as air - conditioning, heating, and adjustable seats can reduce operator fatigue during long work hours.

Wheel loaders are known for their high-capacity buckets. The bucket size can vary widely, from small buckets with a capacity of around 0.5-1 cubic meters for light-duty applications to large buckets that can hold 5-10 cubic meters or more for heavy-construction and mining tasks.

Typically powered by a diesel engine, wheel loaders have engines that deliver high torque. This allows them to start and move heavy loads with ease.

Wheel loaders have a relatively small turning radius compared to other heavy machinery. This allows them to operate effectively in confined spaces such as construction sites, warehouses, and ports.

The hydraulic system is a vital component of a wheel loader. It powers the movement of the loader arms and the bucket. High-pressure hydraulic pumps work in conjunction with cylinders to provide smooth and precise control over the lifting, lowering, and tilting of the bucket.

The operator's cab is designed to provide comfort and safety. It has a good field of vision, with large windows that allow the operator to see the bucket, the loading area, and the surroundings clearly.

The frame of a wheel loader is made of high-strength steel to withstand the heavy loads and the stresses of daily operation. It provides a stable platform for mounting the engine, transmission, axles, and other components.