A motor grader represents a highly significant and specialized construction apparatus. It is equipped with a robust and rigid chassis, an operator's cab furnished with advanced and sophisticated control mechanisms. The machine typically features multiple axles, each fitted with purpose-designed tires to ensure optimal traction and stability on diverse terrains. This enables it to execute a wide array of tasks, including but not limited to grading roads to exacting standards, creating accurate slopes and embankments, and leveling surfaces with meticulous precision. It finds extensive application in the construction, road building, and mining industries.

| Model Name | SEM 917F | SEM 915F | SEM 919F | SEM915 | SEM917 | SEM919 | SEM921 | SEM922AWD |

| Top Speed, Forward | 40km/h | 40km/h | 40km/h | 40km/h | 40km/h | |||

| Blade Width, Standard | 3669mm | 3059mm | 3669mm | 3,059mm (10') | 3,669mm(12'ft) | 3,974mm(13ft) | 4,279mm(14ft) | 4,279mm(14ft) |

| Fuel Tank | 230L | 230L | 230L | 218L | 218L | 320L | 320L | 240L |

| Ground Clearance | 640mm | 615mm | 640mm | 615mm | 640mm | 602mm | 602mm | 602mm |

| Brand / Manufacturer | SEM/Caterpillar | SEM/Caterpillar | SEM/Caterpillar | SEM/Caterpillar | SEM/Caterpillar | SEM/Caterpillar | SEM/Caterpillar | SEM/Caterpillar |

| Brand / Manufacturer | Advance/HangChi | Advance/HangChi | Advance/HangChi | Advance/HangChi | Advance/HangChi | Advance/HangChi | Advance/HangChi | Advance/HangChi |

| Circuit Type | Load Sensing, PPPC | Load Sensing, PPPC | Load Sensing, PPPC | Load Sensing, PPPC | Load Sensing, PPPC | Load Sensing, PPPC | Load Sensing, PPPC | Load Sensing, PPPC |

| Engine Oil | 17.5L | 17.5L | 17.5L | 17.5L | 17.5L | 22L | 22L | 22L |

| Wheel Lean, Left / Right | ±18° | ±18° | ±18° | ±18° | ±18° | ±18° | ±18° | ±18° |

| Engine Manufacturer | SDEC | SDEC | SDEC | SDEC (ShangHai Diesel) | SDEC (ShangHai Diesel) | SDEC (ShangHai Diesel) | SDEC (ShangHai Diesel) | SDEC (ShangHai Diesel) |

| Blade Width, Optional | 3972mm | 3669mm | 3972mm | 3,669mm (12') | 3,972mm(13'ft) | 3,669mm/4,279mm | 3,669/3,974mm | 3,669/3,974mm |

| Pump Type | Variable Piston | Variable Piston | Variable Piston | Variable Piston | Variable Piston | Variable Piston | Variable Piston | Variable Piston |

| Max. Oscillation | ±16° | ±16° | ±16° | ±16° | ±16° | ±16° | ±16° | ±16° |

| Coolant | 37L | 37L | 37L | 37L | 37L | 65L | 65L | 65L |

| Differential | No-Spin | No-Spin | No-Spin | No-Spin | No-Spin | No-Spin | No-Spin | No-Spin |

| Blade Height | 580mm | 580mm | 580mm | |||||

| Type | Converter, Powershift | Converter, Powershift | Converter, Powershift | Convertidor, Powershift | Convertidor, Powershift | Convertidor, Powershift | Convertidor, Powershift | Convertidor, Powershift |

| Standard Weight (Non ROPS base) | 13,500kg | 12,200kg | 14,500kg | |||||

| Engine Model | SC7H170.1G2B | SC7H150G2B | SC7H190.2G2 | SC9D220G2 | SC9D220G2 | |||

| Service Brake | Air over oil, Disc | Air over oil, Disc | Air over oil, Disc | Caliper-Disc | Caliper-Disc | |||

| Transmission | 17L | 17L | 17L | 17L | 17L | 28L | 28L | 28L |

| Standard Weight (with ROPS) | 13,820kg | 12,520kg | 14,820kg | |||||

| Steering Range, Left / Right | ±45° | ±45° | ±45° | ±45° | ±45° | ±47.5° | ±47.5° | ±47.5° |

| Blade Thickness | 20mm | 20mm | 20mm | |||||

| Differential Case | 27L | 27L | 27L | 27L | 27L | 33L | 33L | 33L |

| Forward / Reverse Gears | 6 Forward/ 3 Reverse | 6 Forward/ 3 Reverse | 6 Forward/ 3 Reverse | 6 Forward/ 3 Reverse | 6 Forward/ 3 Reverse | 6 Forward/ 3 Reverse | 6 Forward/ 3 Reverse | 6 Forward/ 3 Reverse |

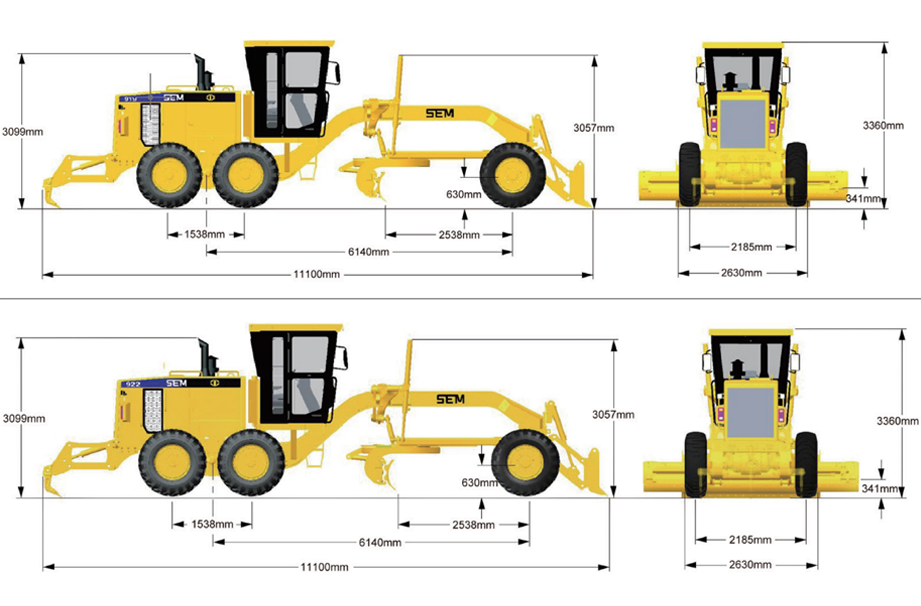

| Overall Dimensions (L*W*H) | 10,723*2,491*3,150mm | 10,723*2,410*3,125mm | 10,723*2,635*3,170mm | 8,516*2,410*3,125 mm | 8,974*2,491*3,150 mm | 8,703*2,630*3,360mm | 8,854*2,630*3,360mm | 8,854*2,630*3,360mm |

| Max. Torque | 750kN @ 1400RPM | 570kN @ 1400RPM | 760kN @ 1400RPM | |||||

| Tandem Case, Each Side | 50L | 50L | 50L | 50L*2 | 50L*2 | 62L*2 | 62L*2 | 62L*2 |

| Oscillation Front Up | 15° | 15° | 15° | 15° | 15° | 15° | 15° | 15° |

| Oscillation Front Down | 25° | 25° | 25° | 25° | 25° | 25° | 25° | 25° |

| Travel Speed (Forward/Reverse) | 40km/h, 29km/h | 40km/h, 29km/h | 40km/h, 25km/h | |||||

| Net Power | 125kW @ 2200RPM | 110kW @ 2200RPM | 140kW @ 2200RPM | |||||

| Circle Drive, Non Slip Clutch | 2L | 2L | 2L | 2L | 2L | 2L | 2L | 2L |

| Circle Drive, With Slip Clutch | 7L | 7L | 7L | 7L | 7L | 7L | 7L | 7L |

| Float Function | YES | YES | YES | Optional | Optional | Optional | Optional | Optional |

| Emission | Tier 2 | Tier 2 | Tier 2 | Tier 2 | Tier 2 | Tier 2 | Tier 2 | Tier 2 |

| Max. Drawbar traction | 75KN | 70KN | 80KN | |||||

| Hydraulic Oil Tank | 55L | 55L | 55L | 55L | 65L | |||

| Frame Articulation Angle | 20° | 20° | 20° | |||||

| Min. Turning Radius | 7300mm | 7300mm | 7300mm | 7300mm | 7300mm | 7,800mm | ||

| Tire | 14-24 12PR | 13-24 12PR | 17.5-25 12PR | |||||

| Max. Cutting Depth | 750mm | 750mm | 750mm | |||||

| Max. Lifting Height | 435mm | 435mm | 435mm |

1. Large Cab

Cab mounted on the front frame provides exceptional view to blade and front axle even during articulation.

Large cab with 1.9m height and 30% larger space than most competitors, provides exceptional comfort.

2. Tandem Axle

Less down time and reduced labor and service cost for maintenance and repairing.

Longer service interval for lubrication oil change.

3. Control System

The link bar is essential for extending reach capability when cutting a bank slope or back slope of a ditch.

4. Blade Float

Provides protection for machine and pavement during snow removal and snow plowing

Consider the Project Requirements

A. Type of Work

1. Road Construction and Maintenance

In road maintenance, a motor grader that can efficiently handle patching and resurfacing tasks is required. It should be able to work on both small and large-scale repairs, such as leveling potholes and ruts or preparing the existing surface for a new layer of asphalt.

2. Site Preparation and Grading

When it comes to site preparation for construction, a motor grader with good material-handling capabilities is beneficial. It should be able to move large volumes of soil, gravel, or other materials and spread them evenly. A wider blade can cover more area in a single pass, which is advantageous for large-scale site-grading projects.

B. Project Scale

1. Small-Scale Projects

For small landscaping projects, a compact motor grader might be sufficient. These smaller graders are more maneuverable and can fit into tight spaces.

2. Large-Scale Projects

For highway construction or large-scale mining operations, a heavy-duty motor grader with a high horsepower engine is necessary. These graders can handle the large volumes of material and long distances involved in such projects. The blade should be long and wide enough to cover a significant area in each pass, reducing the overall grading time.

The blade of a motor grader is typically made of high-strength steel, which provides the necessary rigidity and durability to withstand the forces exerted during grading operations.

Motor grader blades offer a high degree of adjustability.

The chassis and frame of a motor grader are constructed from heavy-duty steel.

Some motor graders feature a suspension system that helps to absorb shocks and vibrations.

The operator's cab of a motor grader is designed with operator comfort in mind.

The controls in the operator's cab are arranged in an intuitive manner.

Motor graders typically have a three-axle configuration, with the front axle being a single-wheel steering axle.

The rear two axles of a motor grader have multiple wheels.

Many modern motor graders are equipped with GPS-based grade-control systems. These systems use satellite signals to accurately determine the position and elevation of the grader's blade.

Motor graders now feature various automated and semi-automated functions.