A Refrigerator Truck is specifically designed to maintain a controlled and low-temperature environment for transporting perishable goods. The truck is typically constructed with a well-insulated body, often made of high-quality polyurethane foam panels, which helps to prevent heat transfer. Inside, it is equipped with a reliable refrigeration unit that can precisely adjust and maintain the desired temperature range, whether it's for transporting fresh produce, dairy products, pharmaceuticals, or frozen items. The truck's interior layout is carefully planned to maximize storage space and ensure proper air circulation. It usually has adjustable shelving and racks to accommodate different types of cargo.

| Transmission Type | Manual |

| Fuel | Diesel |

| Car Type | Van |

| Condition | New |

| Trademark | FBZ brand |

| Driving Type | 4×2, 6×2,left hand drive |

| Engine type | 4 stroke water-cooled, lectric control system |

| No. of cylinders | straight-4 cylinders |

| Emissions standard | Euro 2 |

| Brake | air brake |

| Standard configuration | Air conditioner(optional) |

| Box material | Glass reinforced plastic inside and outside,8cm polyurethane extruded Insulating layer.(if do the van truck,Box matrial:color plate) |

| the internal temperature of the refrigerated body(within) | It is composed of a vehicle-mounted cooling and heating integrated machine and two air mixing air ducts on both sides to realize the circulation of air in the living space of poultry seedlings. And a geothermal ventilation system is installed under the floor. For transportation of one day chicks, maintaining the internal temperature of the van body. |

| Color | According to Customer Requirements |

| Transport Package | Nude with Wax |

| Special function | our refrigerator trucks,whose envelope adopt plastic composite plate structure.internal and external surface is made of galss reinforced plastc and between interal and external is polyurethane extruded Insulating layer. Four sides adopt glass reinforced plastc and polyurethane glue foam bonded together to from a closed section. Envelopes are assembled together with strength adhesion and fatened By inner buried high-strengths screw. |

| Body structure and Insulation | inner plate: fiber glass |

| out plate: fiber glass | |

| keep warm material: 8mm polyurethane foam | |

| 80mm thickness for side and top, 90mm thickness for bottom | |

| All walls and roof panels (internal and external), sub-frames, main-frames and chassis are anti-corrosive treated | |

| The external surface of the body is of a highly reflective finish (e.g., white) and more heat-reflective finish | |

| Heavy duty non slip gritted floor | |

| Fiberglass body with anodized aluminum profile sheathing | |

| The body has drains for release of water | |

| Thermal insulation foaming and refrigerant gas to comply with the requirements of the most recent Montreal Protocol. | |

| Body structure is rigid and capable of withstanding vibrations and shocks from rough roads while keeping the load fully secured when the vehicle is fully loaded. | |

| Door and exhaust fan | Body with two insulated doors at the rear for full width opening. At least two hinges per door. Hinges and closing mechanism is of a robust design. |

| Equipped with an array of high-power exhaust fans, a manual door for skylights, and several shutters on the front and side panels. |

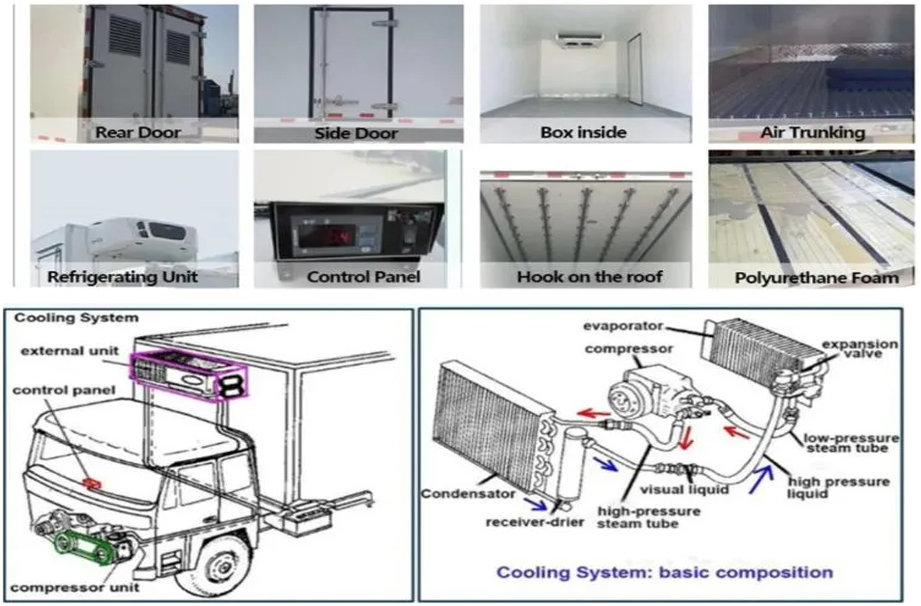

1. The chassis is the base of the refrigerator truck and is usually a heavy-duty vehicle frame. It provides the structural support for the entire unit and determines the truck's load-carrying capacity.

2. The insulated body is a crucial component that creates a temperature-controlled environment. It is usually made of panels constructed from materials like polyurethane foam sandwiched between two metal sheets. The insulation thickness can vary, but it is designed to minimize heat transfer between the inside and outside of the truck.

3. The refrigeration unit is the heart of the system. It is typically mounted on the front or top of the insulated body. There are different types of refrigeration systems, including compressor-based units.

4. An efficient air circulation system is essential to ensure an even temperature distribution throughout the cargo area. It usually consists of fans and ducts. The fans help to circulate the cold air, preventing hot spots and ensuring that all the products are kept at the desired temperature.

5. Inside the truck, there are often adjustable shelves, racks, and tie-down points. The shelves and racks can be configured according to the size and shape of the cargo to maximize storage space.

1. Temperature Range: Determine the specific temperature range needed for the goods you'll be transporting. For fresh produce like fruits and vegetables, a temperature range of 0 - 4°C (32-39.2°F) is usually ideal. For frozen foods such as ice cream and frozen meats, a temperature of -18°C (0.4°F) or lower is required. Make sure the refrigerator truck you choose can maintain the appropriate temperature range precisely.

2. Cargo Volume: Consider the volume of goods you need to transport regularly. Refrigerator trucks come in various sizes, from small vans with a few cubic meters of cargo space to large semi-trailers with significant capacity.

3. Insulation Material: Check the type and quality of the insulation used in the truck's body. High-density polyurethane foam is a common and effective insulation material.

4. Energy Efficiency: Look for a refrigeration unit that is energy-efficient. This not only helps to reduce operating costs but also has a positive impact on the environment.

5. Engine and Transmission: If the refrigerator truck is a self-propelled vehicle, the engine and transmission are important factors.

Refrigerator trucks are equipped with high-quality insulation materials. The body panels are usually filled with polyurethane foam, which has excellent thermal-insulating properties.

These trucks have advanced refrigeration units that allow for precise temperature control. The temperature can be adjusted according to the type of cargo being transported.

A well-designed air circulation system is a key feature. Inside the truck, fans and ducts work together to ensure even distribution of cold air.

Refrigerator trucks have a robust frame and body to withstand the rigors of transportation. The chassis is usually heavy-duty to support the weight of the insulated body and the cargo.

The interior of a refrigerator truck offers versatile cargo-handling capabilities. It often has adjustable shelves and racks that can be configured to fit different sizes and shapes of packages.

The refrigeration system is not only precise in temperature control but also reliable. It typically consists of a compressor, condenser, evaporator, and a thermostat.