Skid steer loaders are compact and highly maneuverable workhorses in the construction and landscaping fields. Their unique design features a rigid frame with wheels or tracks set close together, allowing for a zero-turn radius. The front-mounted bucket, available in various sizes, can scoop, lift, and dump materials like dirt, gravel, and snow with ease. Powered by a potent engine, they deliver sufficient power to handle heavy loads. The operator's cab is ergonomically designed, providing excellent visibility and intuitive controls. Whether it's site prep, material handling, or snow removal, skid steer loaders prove indispensable, fitting into tight spaces and getting the job done efficiently.

| Performance Parameters | |||||||||||||

| Operating load(kg) | 380 | 500 | 700 | 850 | 1050 | 1100 | 1200 | 700 | 1000 | 1200 | 1500 | 500 | 850 |

| Max Speed(km/h) | 9 | 10 | 12 | 12 | 12 | 9\18 | 9\18 | 10 | 12 | 9\18 | 9\18 | 6 | 6 |

| Rated flux(L/min) | 50 | 60 | 62.5 | 75 | 75 | 75 | 75 | 60 | 80 | 88 | 88 | 60 | 75 |

| High Flow Flux (L/min) | / | / | / | / | 120 | 140 | 140 | / | 120 | 140 | 140 | / | / |

| Tire(track )model | 5.7-12 | 8.5-15 | 10-16.5 | 12-16.5 | 12-16.5 | 12-16.5 | 12-16.5 | 300X52.5 | 320X86 | 320X86 | 450X86 | 28*9-15 | 28*9-15 |

| Rated power (Kw) | 18.7 | 37 | 37 | 45 | 55 | 74 | 103 | 36 | 55 | 74 | 103 | 37 | 45 |

| Fuel tank capacity(L) | 28 | 60 | 70 | 80 | 75 | 90 | 90 | 50 | 90 | 90 | 90 | 60 | 80 |

| self weight bucket (kg) | 1300 | 2300 | 2700 | 2800 | 3500 | 3550 | 3600 | 2800 | 3800 | 4500 | 4800 | 2300 | 2800 |

| Bucket capacity(m3) | 0.19 | 0.3 | 0.4 | 0.4 | 0.5 | 0.55 | 0.55 | 0.3 | 0.5 | 0.55 | 0.6 | 0.3 | 0.4 |

| Dimensional parameters | |||||||||||||

| Overall operating height (mm) | 3552 | 3300 | 3980 | 4000 | 4070 | 4070 | 4070 | 3350 | 3480 | 4070 | 4070 | 3310 | 3770 |

| Height to bucket hinge pin (mm) | 2642 | 2725 | 3080 | 3100 | 3280 | 3280 | 3280 | 2770 | 2900 | 3280 | 3280 | 2320 | 2810 |

| Height to top of cab (mm) | 1900 | 2000 | 2140 | 2160 | 2160 | 2160 | 2160 | 2050 | 2150 | 2160 | 2160 | 1500 | 1600 |

| Height to bottom of level bucketímm) | 2446 | 2558 | 2913 | 2933 | 3140 | 3140 | 3140 | 2603 | 2730 | 3140 | 3140 | 2160 | 2643 |

| Without bucket length(mm) | 2267 | 2300 | 2640 | 2750 | 2880 | 2880 | 2880 | 2300 | 2750 | 3000 | 3000 | 2400 | 2800 |

| Overall length with bucket(mm) | 2959 | 2950 | 3420 | 3490 | 3580 | 3580 | 3580 | 2950 | 3500 | 3700 | 3700 | 3150 | 3490 |

| Dumping angle at maximum height(°) | 40 | 40 | 40 | 40 | 40 | 40 | 40 | 40 | 40 | 40 | 40 | 40 | 40 |

| Dumping height(mm) | 1933 | 2050 | 2380 | 2400 | 2500 | 2500 | 2500 | 2100 | 2230 | 2500 | 2500 | 1550 | 2080 |

| Dumping reach(mm) | 441 | 790 | 700 | 750 | 700 | 700 | 700 | 790 | 715 | 700 | 700 | 660 | 700 |

| Rollback o bucket on ground(°) | 30 | 30 | 30 | 30 | 30 | 30 | 30 | 30 | 30 | 30 | 30 | 30 | 30 |

| Rollback of bucket at full height(°) | 103 | 104 | 104 | 104 | 104 | 104 | 104 | 104 | 104 | 104 | 104 | 104 | 104 |

| Wheelbase(mm) | 801 | 897 | 991 | 991 | 1080 | 1115 | 1115 | 1240 | 1500 | 1500 | 1500 | 897 | 991 |

| Ground clearance(mm) | 145 | 140 | 185 | 205 | 205 | 205 | 205 | 140 | 200 | 200 | 200 | 150 | 205 |

| Angle of departure(°) | 20 | 20 | 20 | 20 | 20 | 20 | 20 | 20 | 20 | 20 | 20 | 20 | 20 |

| Front turning radius without bucket(mm) | 960 | 1098 | 1168 | 1198 | 1250 | 1278 | 1278 | 1064 | 1298 | 1365 | 1365 | 1098 | 1228 |

| Front tuning radius(mm) | 1660 | 1760 | 1958 | 1958 | 2112 | 2144 | 2144 | 1825 | 2010 | 2200 | 2200 | 1760 | 2010 |

| Rear tuning radius(mm) | 1253 | 1296 | 1630 | 1728 | 1774 | 1857 | 1857 | 1264 | 1714 | 1742 | 1742 | 1296 | 1746 |

| Rear axle to bumper(mm) | 910 | 964 | 1108 | 1208 | 1082 | 1082 | 1082 | 594 | 890 | 938 | 938 | 964 | 1208 |

| Tread width(mm) | 785 | 1080 | 1450 | 1500 | 1500 | 1500 | 1500 | 1102 | 1462 | 1654 | 1654 | 1080 | 1450 |

| Width(mm) | 927 | 1350 | 1720 | 1880 | 1880 | 1880 | 1880 | 1402 | 1782 | 1994 | 2124 | 1380 | 1720 |

| Bucket width(mm) | 915 | 1400 | 1740 | 1880 | 1880 | 1880 | 1880 | 1500 | 1830 | 2030 | 2160 | 1400 | 1740 |

1. Frame: The frame is a robust, welded steel structure that forms the backbone of the loader. It provides the necessary rigidity to withstand the forces generated during operation.

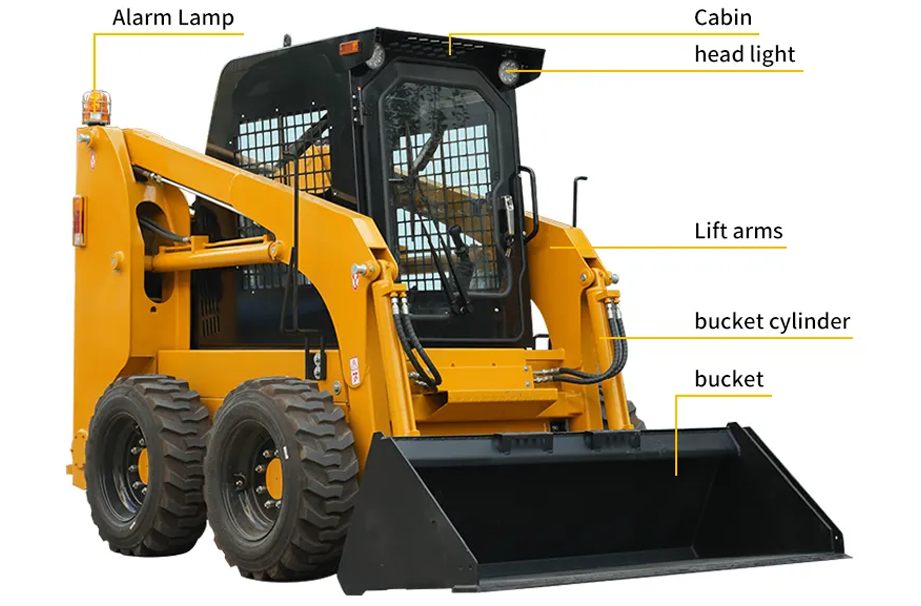

2. Lift Arms: Attached to the front of the frame, the lift arms are powered by hydraulic cylinders. They are responsible for raising and lowering the bucket.

3. Bucket: The front-mounted bucket comes in various shapes and sizes to suit different tasks. General-purpose buckets have a flat bottom and are good for scooping loose materials like soil and gravel.

4. Hydraulic Pump: The heart of the hydraulic system, the pump pressurizes the hydraulic fluid.

5. Hydraulic Cylinders: These cylinders convert the hydraulic pressure into mechanical force.

6. Hoses and Valves: High-quality hoses carry the hydraulic fluid between components, while valves regulate the flow and direction of the fluid.

7. Engine: Usually a diesel or gasoline engine, it provides the power to drive the hydraulic pump and move the loader.

8. Transmission: The transmission system transfers power from the engine to the wheels or tracks. There are different types, such as hydrostatic transmissions, which offer smooth acceleration and precise speed control.

9. Wheels: Some skid steer loaders use wheels, which provide good mobility on hard, flat surfaces. They are often equipped with large, wide tires to increase traction and stability.

10. Tracks: Tracked skid steer loaders are better suited for soft, muddy, or uneven terrains. The tracks distribute the weight of the loader more evenly, reducing ground pressure and preventing sinking.

1. Bucket Capacity and Loading Requirements: Determine the volume of materials you need to move regularly. Bucket capacities for skid-steer loaders can range from a few cubic feet to over a cubic yard.

2. Lifting Capacity: Check the maximum weight the loader can lift. This is crucial if you plan to lift heavy objects such as pallets of bricks or large boulders.

3. Terrain Conditions: Consider the type of ground where the loader will be used. For smooth, hard surfaces like paved industrial yards, a wheel-based skid-steer loader might be sufficient.

4. Space Constraints: Skid-steer loaders are known for their compact size and maneuverability. If you'll be operating in tight spaces like small warehouses, urban construction sites, or narrow alleys, choose a loader with a small footprint and a tight turning radius.

5. Engine Power: A powerful engine is essential for efficient operation. Look for a loader with sufficient horsepower and torque to handle the workload.

6. Hydraulic System Performance: The hydraulic system powers the movement of the lift arms and bucket. Check the flow rate and pressure of the hydraulic pump.

7. Size and Weight: Consider the overall size and weight of the loader. A lighter-weight loader might be more mobile and easier to transport, but it could sacrifice stability and lifting capacity.

8. Versatility: Skid-steer loaders are highly versatile due to their ability to use a wide range of attachments. Ensure the loader you choose is compatible with the attachments you need.

Skid-steer loaders are renowned for their compact size and zero-turn radius. The close-set wheels or tracks allow the loader to pivot in place.

One of the most significant features is their ability to use a wide variety of attachments. The quick-attach system at the front end allows for easy swapping of different tools.

A robust hydraulic system is at the heart of a skid-steer loader's operation. The hydraulic pump pressurizes the fluid to power the lift arms and bucket. The system provides the force necessary for lifting heavy loads and allows for precise control of the movements.

Despite their small size, skid-steer loaders offer high productivity. Their compact frame doesn't sacrifice performance. They can quickly scoop and transport materials, with efficient cycle times.

The operator's cab is designed with comfort and functionality in mind. It provides excellent visibility of the work area through large windows and well-placed mirrors. The controls are intuitive, usually with joystick-based operation for the lift arms and bucket.

Skid-steer loaders can be equipped with either wheels or tracks, depending on the terrain requirements. Wheel-equipped loaders are more suitable for hard, smooth surfaces and offer good mobility.