A soil compactor is a vital construction machine. It has a robust chassis and a powerful engine. The key component is the compaction unit, which can be a drum or a plate. Drum compactors, with their vibration and weight, are highly effective for granular soils like sand and gravel, quickly rearranging the particles. For cohesive soils such as clay, padfoot drum compactors with their protruding feet are more suitable as they can better penetrate and knead the material. Plate compactors, which rely on impacts, work well on both granular and cohesive soils in smaller areas or confined spaces. It's crucial for enhancing soil density, providing stable foundations, and is widely used in construction, road building, and landscaping.

| Model Name | SEM510 | SEM512 | SEM518 | SEM520 |

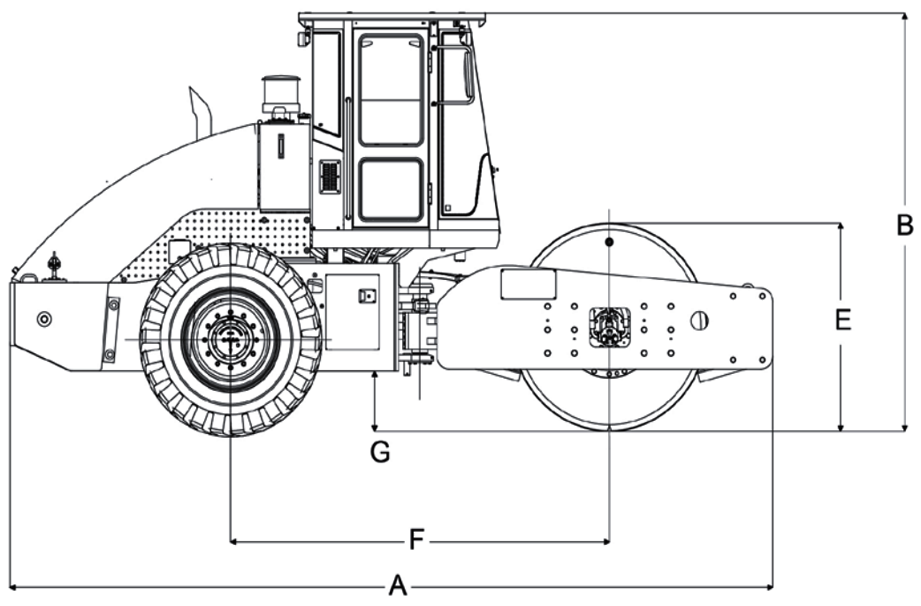

| Machine Dimensions [L*W*H] | 5,815*2,290*3,130mm | 5,815*2,290*3,130mm | 6.250*2.310*3.200mm | 6.250*2.310*3.200mm |

| Model | WP4G | WP4G | WP6G | WP6G |

| Tire Specs | 23.1-26 12PR | 23.1-26 12PR | 20.5-25PR | 20.5-25PR |

| Lo Range | 0 to 5.5km/h | 0 to 5.5km/h | ||

| Hi Range | 0 to 12km/h | 0 to 12km/h | ||

| Amplitude-Hi/Lo | 1.80/0.90mm | 1.80/0.90mm | 2/1mm | 2/1mm |

| Tire Pressure Setting | 0.20Mpa/29psi | 0.20Mpa/29psi | 0.35Mpa/51psi | 0.35Mpa/51psi |

| Machine Mass w/Std Config | 10,000kg | 12,000kg | 18,000kg | 20,000kg |

| Emission | TIER II | TIER II | TIER II | TIER II |

| Hydraulic Oil Tank Volume | 22L | 22L | 80L | 80L |

| F/R I | 2.98km/h | 2.98km/h | ||

| F/R II | 5.88km/h | 5.88km/h | ||

| Wheelbase | 2,900mm | 2,900mm | 3.100mm | 3.100mm |

| Rated Speed | 2,200rpm | 2,200rpm | 2,000rpm | 2,000rpm |

| F/R III | 9.60km/h | 9.60km/h | ||

| Weight at Drum w/Std Config | 5,900kg | 6,900kg | 9,000kg | 10,000kg |

| Drum Diameter | 1,600mm | 1,600mm | 1,600mm | 1,600mm |

| Weight on Rear Axle | 4,100kg | 4,100kg | 9,000kg | 10.000kg |

| Static Linear Load | 217N/cm | 217N/cm | 415N/cm | 461N/cm |

| Drum Thickness | 20mm | 25mm | 40mm | 40mm |

| Max. Grade Ability w/o vibbration | 45% | 45% | 34% | 34% |

| Articulated Angle | 33±1° | 33±1° | 33±1° | 33±1° |

| Turning Radius Inside Drum Edge | 5,990mm | 5,990mm | 6,350mm | 6,350mm |

| Fuel Tank Volume | 200L | 200L | 262L | 262L |

| Steering Angle | ±33° | ±33° | ±33° | ±33° |

| Oscilation Angle | ±10° | ±10° | ±12° | ±12° |

I. The Chassis

1. The chassis of a soil compactor is predominantly constructed from high-strength steel.

2. The design of the chassis incorporates strategic reinforcements and cross-members.

II. The Compaction Unit

1. The drum of a drum compactor is a large, cylindrical component that plays a central role in the compaction process.

2. Many drum compactors are equipped with a vibration system to enhance the compaction process.

3. Plate compactors feature a flat, rectangular or circular plate as the compaction unit. The plate is made of steel and is attached to a set of springs or a hydraulic system.

4. Plate compactors can be equipped with various attachments and have adjustable features.

III. The Power Source and Transmission

1. Soil compactors are commonly powered by diesel engines due to their high-torque output characteristics.

2. The engine is mounted on the chassis in a way that minimizes the transmission of vibrations to the rest of the machine.

3. The transmission system of a soil compactor is responsible for transferring power from the engine to the wheels or tracks and the compaction unit.

Consider the Compactor's Specifications

A. Compaction Unit Specifications

1. Drum Compactors

Drum Size and Weight: The size (diameter and width) and weight of the drum affect the compaction force and coverage area.

Drum Surface and Features: As mentioned earlier, the drum surface can be smooth, padfoot, or have other textures.

Vibration System (if applicable): The vibration characteristics of a drum compactor, including the frequency and amplitude, play a crucial role in compaction.

2. Plate Compactors

Plate Size and Shape: The size and shape of the plate influence the area covered and the compactor's maneuverability.

Plate Movement and Impact Force: For plate compactors, the way the plate moves (up-and-down movement frequency and height) and the resulting impact force are important.

B. Power and Mobility

1. Engine Power

The power of the compactor's engine determines its ability to handle different soil types and compaction tasks.

The type of engine (usually diesel) and its fuel consumption are also factors.

2. Mobility Features

Wheels and Tracks: Soil compactors can have either wheels or tracks.

Steering and Maneuverability: Good steering and maneuverability are essential, especially for working in confined spaces or around obstacles.

The drum is a central component of drum compactors. It is typically made of heavy-duty steel to withstand the forces exerted during compaction.

Many drum compactors are equipped with a vibration system. The vibration is generated by an eccentric shaft or weights inside the drum.

Plate compactors have a flat plate as the compaction unit. The plate is made of steel and is attached to a set of springs or a hydraulic system.

The chassis and frame of a soil compactor are built from heavy-duty steel. This provides a solid foundation for the machine and enables it to withstand the stresses and vibrations of the compaction process.

Soil compactors are usually powered by diesel engines due to their high-torque output. The power output of the engine is chosen based on the size and requirements of the compactor.

The transmission system of a soil compactor is responsible for transferring power from the engine to the wheels or tracks and the compaction unit.

The operator's cab is designed to provide a comfortable and safe working environment. It has an adjustable seat with good lumbar support and cushioning to reduce operator fatigue.

Wheeled soil compactors have wheels that provide mobility. The front wheel is often used for steering, and the rear wheels support the weight of the compactor and provide traction.

Tracked compactors have a track system instead of wheels. The tracks provide excellent traction and stability, especially on soft and muddy terrains.