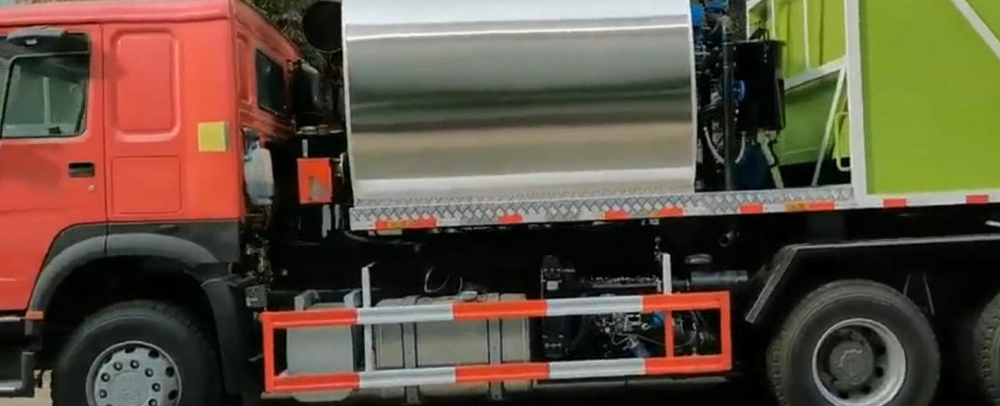

A synchronous chip sealer is an advanced road maintenance equipment. It is designed to simultaneously apply asphalt binder and aggregate chips onto the road surface. The machine consists of an asphalt tank, a chip hopper, and a spreading system. The asphalt is sprayed evenly while the chips are precisely dispensed and spread. It has a control unit that ensures synchronized operation, maintaining accurate ratios of asphalt to chips. This equipment is highly efficient in enhancing road durability and skid resistance, effectively sealing and protecting the pavement, and is widely used in road rehabilitation and preventative maintenance projects.

| The Specification of 12CBM Synchronous Chip Sealer | ||||

| Mass parameter: | ||||

| curb Weight(kg) | 21200 | Total Weight ( kg ) | 31000 | |

| Rated loading Weight(kg) | 9670 | Dimension(mm) | 12000 × 2500 × 3730 | |

| Chassis Parameter : | ||||

| Chassis Model | ZZ1317N4647C | Tyre model | 12.00-20 , 12.00R20 | |

| Wheelbase (mm) | 1800+4600+1350 | Tread mm | 2022/1830 | |

| Engine parameter : | ||||

| Engine model | WD615.95 | |||

| Max.Power(kw) | 247 | Max. Torque(N.m) | 1300/1600 | |

| Fuel | Diesel | Displacement(ml) | 9726 | |

| Chip sealer specification : | ||||

| Tank Capacity(m³) | 12 | Spray width | 3800mm | |

| Hydraulic pump model | CBQL-E563 | Spray Value | 0.5-3.0 ( Kg ) | |

| Hydraulic moto r | L2F63W2P2 ( Liyuan ) | Insulation Thickness | 50mm | |

| Controller | ZM-3D | Nozzles | 32 | |

| Generator(Converter) | YT6800T | Burner | G20 ( Riel-lo ) | |

| Asphalt pump | QGB450 ( Shanggui ) | Chipping capacity(m ) | 12m3 | |

1. The chassis of a synchronous chip sealer is the base structure that provides support and mobility. It's usually a heavy-duty, self-propelled chassis or can be trailer-mounted and towed by a truck.

2. The asphalt system is a crucial part of the synchronous chip sealer. It consists of an asphalt tank, a pump, and a spray bar. The asphalt tank is designed to store a specific volume of hot liquid asphalt.

3. The chip hopper is used to store the aggregate chips. It's typically made of steel and has a large capacity to hold an adequate amount of chips for continuous operation. The hopper is designed with a sloping bottom to ensure the chips feed smoothly into the spreading system.

4. The control system of a synchronous chip sealer is what enables the synchronized operation of the asphalt spraying and chip spreading. It's usually located in a control cabin or panel that provides the operator with a good view of the operation.

5. The power system provides the energy needed to operate the various components of the synchronous chip sealer. It can be a diesel-powered engine that drives the asphalt pump, the chip conveyor, and other mechanical parts.

1. Asphalt Capacity: The size of the asphalt tank is a crucial factor. For small-scale road maintenance jobs or projects covering short distances, a tank with a capacity of 1,000-3,000 liters might be sufficient.

2. Chip Hopper Capacity: Consider the volume of the chip hopper. A larger hopper can hold more aggregate chips and reduces the need for frequent refilling.

3. Treatment Width and Speed: Look at the maximum width of treatment the sealer can provide and its working speed. A wider treatment width and a faster working speed are beneficial for large-area projects.

4. Asphalt Spraying Precision: The sealer should have a high-quality asphalt spraying system. The nozzles should be adjustable to achieve different spray patterns and widths.

5. Chip Spreading Uniformity: The chip spreading system should be able to spread the aggregate chips evenly over the asphalt.

6. Chassis Type and Mobility: Consider whether you need a self-propelled sealer or a trailer-mounted one. Self-propelled sealers offer more independence in movement but are generally more expensive.

7. Maneuverability: If you'll be working on narrow roads or in areas with limited space, the sealer's maneuverability is crucial.

8. Ease of Use: The control system should be user-friendly. It should have clear and intuitive controls such as levers, buttons, or touch-screen interfaces.

The most distinctive feature of a synchronous chip sealer is its ability to synchronize the application of asphalt binder and aggregate chips. It ensures that the chips are spread immediately after the asphalt is sprayed onto the road surface.

The asphalt spraying system of a synchronous chip sealer is designed for high precision. It includes an asphalt tank, a pump, and a spray bar with multiple nozzles. The tank is usually insulated and has a heating system to keep the asphalt in a liquid state.

The chip spreading component is equally important. The sealer has a chip hopper with a large capacity to store the aggregate chips. The hopper is designed with a sloping bottom to ensure a smooth flow of chips to the spreading mechanism.

By simultaneously applying asphalt and chips, a synchronous chip sealer significantly improves the road's durability and skid resistance. The layer of chips provides a rough texture that enhances traction, especially in wet or slippery conditions.

The sealer is equipped with a user-friendly control system. The operator can adjust various parameters such as the speed of the sealer, the asphalt spray width and pressure, the chip spread width and rate, and the overall treatment rate.