Telescopic loaders are highly versatile heavy machinery. They feature a telescopic boom that can extend and retract, providing an impressive reach and lift height. This allows them to access materials in hard-to-reach places, like the back of a high-sided truck or atop a storage stack. The front-mounted bucket or other attachments can handle diverse loads, from loose soil and gravel to palletized goods. Powered by a robust engine, they offer sufficient strength for heavy-duty tasks. The operator's cab is designed for comfort, with good visibility and ergonomic controls. Ideal for construction sites, farms, and warehouses, telescopic loaders enhance efficiency and productivity.

| Performance | rated loading (kg) | 2500 |

| overall weight (kg) | 6700 | |

| rated bucket capacity (CBM) | 1.1 | |

| maximum tractive force (kN) | 45 | |

| maximum breakout force (kN) | 35 | |

| maximum grade ability(°) | 35 | |

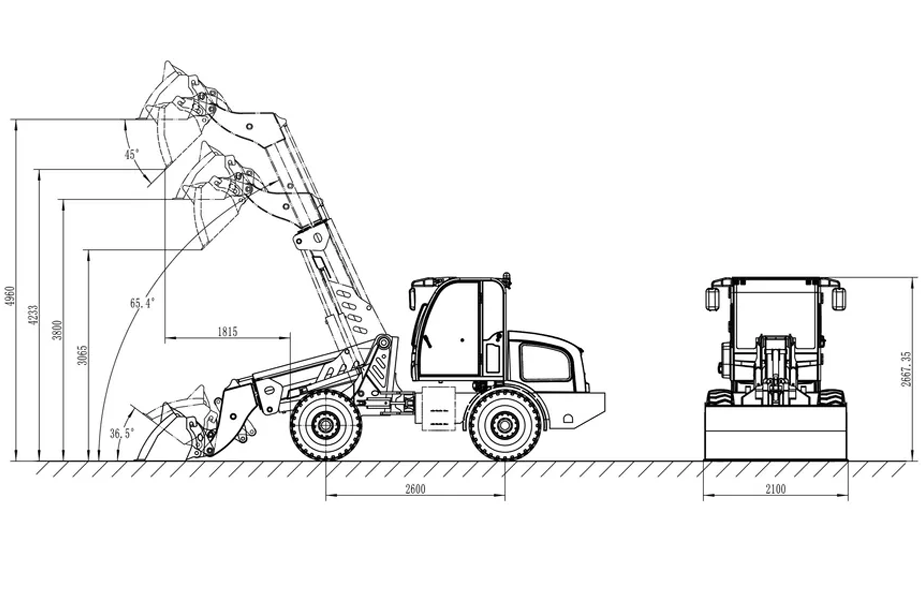

| most lift height(mm) | 5000 | |

| maximum dump height(mm) | 4350 | |

| maximum dump height(mm) | 3180 | |

| maximum dump reach(mm) | 1300 | |

| overall dimension (L×W×H) (mm) | 6700*2070*2680 | |

| minimum turning radius(outside of wheels)(mm) | 4400 | |

| maximum steering angle | 35° | |

| Oscillation angle | 7° | |

| Engine | model | CHANGCHAI 4G33 70kw/YUNNEI EURO V/YAMMAR EURO V/ EPA 4 |

| type | lnline water cooled, four stroke | |

| No. of cylinder-bore/stroke (mm) | 4-102×118 | |

| displacement (L) | 3.856 | |

| rated power(kW) | 65 | |

| idel speed (r/min) | 800-850 | |

| rated speed (r/min) | 2400 | |

| maximum torque N.m @speed r/min | 300 @ 1500-1700 | |

| min fuel-consume ratio | ≤230g/kw.h | |

| Transmission system | torque converter | 280 |

| gearbox mode | Power shift normally engaged straight gear | |

| gear shift | Mechanical, 2forward shift 2 reverse shift and another more high speed | |

| maximum speed | 30km/h,40km/h | |

| Drive axles | main reducing mode | Bevel gear grade l reduction |

| wheel base (mm) | 2480 | |

| wheel tread(mm) | 1680 | |

| ground clearance(mm) | 330 | |

| Hydraulic system | system working pressure (Mpa) | 20 |

| boom lifting time (s) | 6.4 | |

| total time (s) | 11.5 | |

| fuel tank capacity (L) | 94 | |

| Brake system | service brake | Air-assist hydraulic brake, disc brake |

| parking brake | Manual disc brake | |

| Tyre | type specification | 16/70-20 |

| front tyre pressure (kPa) | 350 | |

| rear tyre pressure (kPa) | 350 |

1. The chassis is a heavy-duty, welded steel structure that forms the base of the loader. It provides the essential stability and strength to support the entire machine. The frame is designed to evenly distribute the weight of the loader, including the load it's carrying and the telescopic boom.

2. The telescopic boom is the standout feature of this loader. It consists of multiple nested sections that can slide in and out relative to each other. Made of high-strength steel, it can extend to achieve a significant reach and lift height.

3. Telescopic loaders are known for their versatility, largely due to their attachment system. The front end of the boom has a quick-attach mechanism that allows for easy swapping of different attachments.

4. Hydraulic Pump: The heart of the hydraulic system, the pump pressurizes the hydraulic fluid. It's usually driven by the engine and provides the necessary pressure to power the movements of the telescopic boom, attachment, and other hydraulic functions.

5. Hydraulic Cylinders: These cylinders convert the hydraulic pressure into mechanical force. In the case of the telescopic loader, they control the extension and retraction of the boom as well as the operation of attachments.

6. Hoses and Valves: High-quality hoses carry the hydraulic fluid between components, while valves regulate the flow and direction of the fluid.

7. The engine is the power source of the telescopic loader. It's typically a diesel engine, known for its high-torque output. The engine provides the energy to drive the hydraulic pump and move the loader itself.

1. Determine the maximum reach and lift height you require. Consider the specific tasks such as loading trucks with high sides, stacking materials in tall storage racks, or reaching over obstacles.

2. Check the maximum weight the loader can lift. This is crucial if you plan to handle heavy objects like large pallets of construction materials or agricultural bales.

3. Consider the type of ground where the loader will be used. If it's a rough construction site or an agricultural field with uneven surfaces, you'll need a loader with good ground clearance and durable tires.

4. In confined work areas like small construction yards or warehouses, a telescopic loader with a small turning radius and a compact body is essential.

5. A powerful engine is necessary for handling heavy loads and operating the telescopic boom smoothly. Look for a loader with sufficient horsepower and torque.

6. The transmission type also matters. Automatic or hydrostatic transmissions offer smoother operation and are easier to handle, while manual transmissions may provide more control in some situations.

7. The hydraulic system powers the movement of the telescopic boom and attachments. Check the flow rate and pressure of the hydraulic pump.

8. Telescopic loaders are highly versatile due to their ability to use a wide range of attachments. Ensure the loader you choose is compatible with the attachments you need.

Telescopic loaders are equipped with a telescopic boom that can extend and retract, providing an extraordinary range. This allows them to access areas that would be difficult or impossible for other loaders.

One of the standout features is their ability to use a wide array of attachments. Thanks to a quick-attach system, the front of the boom can be fitted with different tools. Standard buckets come in multiple sizes for scooping soil, gravel, and other loose materials.

A robust hydraulic system is at the heart of a telescopic loader's operation. The hydraulic pump, driven by the engine, pressurizes the fluid to power the movement of the telescopic boom and attachments. The system provides the force needed to lift heavy loads and allows for precise control.

The operator's cab is designed with the comfort and convenience of the operator in mind. It offers excellent visibility of the work area through large windows and well-placed mirrors. The controls are intuitive, usually with joystick-based operation for the telescopic boom and attachment.

Telescopic loaders are built with a heavy-duty frame and components. The telescopic boom, made of high-strength steel, can withstand the stress of heavy loads and frequent use.