A Truck Mounted Crane is a highly versatile vehicle. It combines a robust truck chassis with a powerful crane mechanism. The crane, usually made of strong steel, has a telescopic boom that can extend and retract, allowing for various lifting heights and reaches. It's suitable for a wide range of applications, such as construction site material handling, loading and unloading heavy equipment. The truck provides mobility, enabling the crane to be easily transported to different locations. The cab is designed for operator comfort and control. With safety features and precise control systems, it offers efficient and reliable lifting operations.

| Model Name | Self loader truck/boom crane |

| Driving Type | 6x4, left hand drive |

| Weights | |

| GVW(kg) | 25000 |

| Tare weight(kg) | Aprro 14000 |

| Loading capacity(kg) | 10000 |

| Dimensions | |

| Wheelbase(mm) | 5700+1300 |

| Overall Dimension(mm) | Appro 11750×2550×3950 |

| Cargo dimension(mm) | |

| Max speed(km/h) | 95 |

| Engine | |

| Engine model | 6HK1-TCH(300HP) |

| Emission standard | Euro V |

| Engine type | Diesel 4-storke |

| Inter-cooling, water-cooled | |

| No. of cylinders | 6 cylinders |

| Displacement(L) | 7.79 |

| Rated power Rev((Kw/rpm) | 221kw |

| Drive Line | |

| Transmission | FAST:9 forward gears, 1 reverse gear, manual operation |

| Steering | Power steering |

| Cab | |

| cabin | I SUZU FVZ |

| Standard configuration | Air container ,Sound,USD,electrical windows ,oil pressure gauge, air pressure,fule level indicator,battery charge indicator,Temperature indicator, thermometer, H and so on |

| Axle | |

| Front axle | 7 tons |

| Rear axle | 18tons x2 |

| Tire specification | |

| Tire specification | 11.00R20 |

| Tire quantity | 10 tires+1 spare tire |

| Flat bed/ Carrying body | |

| Flat bed+ slope(mm) | 8150x2500 |

| Drop side | 550mm height, be removable |

| Climbing ramp for vehicle | 2 units, hydraulic system control |

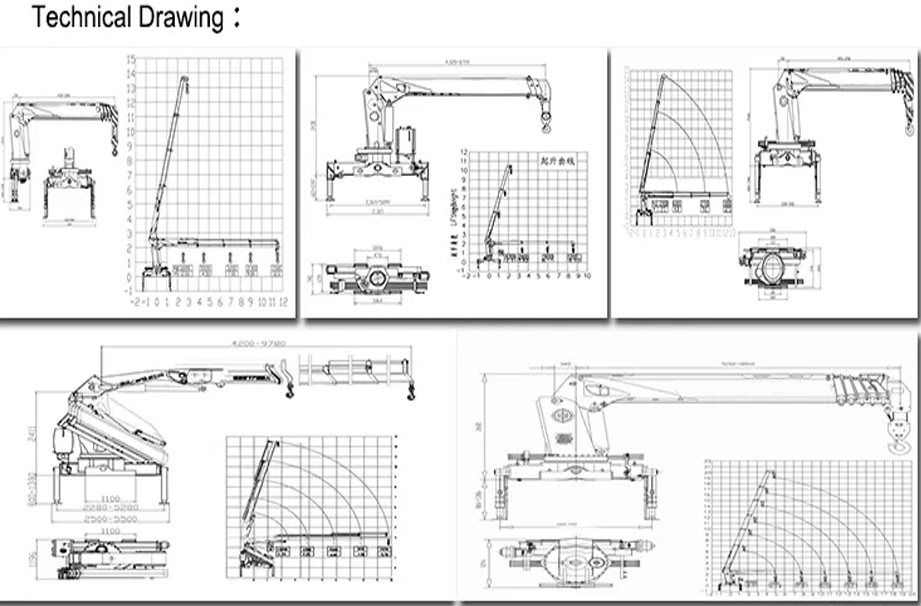

| Crane parameters | |

| Model | SQ10SK3Q (New model: SQS250) |

| Booms | 4 |

| Max Lifting weight | 10000KG |

| Lifting Torque | 25T.M |

| Rated Pressure of Hydraulic System | 26MPA |

| Hydraulic Tank Volume | 160L |

| Max Flow of Hydraulic System | 63L/MIN |

| Rotation Angle | 360° all around |

1. The truck chassis is the base of the vehicle-mounted crane. It's a heavy - duty structure, typically made of high-strength steel. The chassis provides the necessary support to carry the weight of the crane, the load being lifted, and other equipment.

2. The crane boom is a central component. It's usually made of high-quality steel and can be of different types, such as telescopic or lattice-style. The telescopic boom is popular for its ability to extend and retract, allowing for variable lifting heights and reaches.

3. The hydraulic system powers the movement of the crane. It includes a hydraulic pump, usually driven by the truck's engine via the PTO. The pump pressurizes the hydraulic fluid, which is then directed to various hydraulic cylinders through a network of hoses and valves.

4. Outriggers are essential for stability during lifting operations. They are usually extendable arms that can be deployed from the sides of the truck. When extended, they provide a wider base of support and help distribute the load more evenly.

5. The cab is designed for the operator's comfort and efficient operation. It has an ergonomic seat to reduce fatigue during long work hours. The controls for operating the truck and the crane are laid out in an intuitive manner.

6. The truck-mounted crane is equipped with various load-handling devices. This includes hooks, slings, and spreader bars. The hooks are usually made of high-strength alloy steel and can handle heavy loads.

1. Lifting Capacity: Determine the maximum weight you need to lift. Consider the heaviest loads you'll handle regularly, such as construction materials, machinery, or containers.

2. Boom Reach: Assess the required reach of the crane. The reach is the horizontal distance the crane can extend to place a load.

3. Chassis Strength: The truck chassis must be strong enough to support the weight of the crane and the load.

4. Vehicle Mobility: Consider the mobility of the truck. Ensure it can access your job sites easily. Factors such as the truck's size, turning radius, and ground clearance are important.

5. Boom Type: Decide between a telescopic or lattice-style boom. Telescopic booms are more versatile for variable lifting heights and reaches, as they can extend and retract.

6. Boom Length and Sections: The length of the boom affects the reach and lifting height. Also, check the number of boom sections if it's a telescopic boom.

7. Power and Precision: The hydraulic system should provide enough power to operate the crane smoothly and quickly.

8. Reliability and Maintenance: Look for a hydraulic system known for its reliability. Fewer moving parts and easy-to-maintain components reduce the risk of breakdowns.

9. Outrigger Design: Examine the outrigger design. They should be easy to deploy and adjust to different ground conditions.

10. Stability Requirements: Consider the stability requirements of your lifting operations.

11. Operator's Comfort: The cab should have an ergonomic seat to reduce operator fatigue during long workdays.

12. Control System: The control system should be intuitive and easy to use. Look for controls such as joysticks, pedals, and switches that provide precise control of the crane's movements.

The truck-mounted crane's most prominent feature is its lifting capacity. With a strong steel crane structure, it can handle heavy loads ranging from a few tons to a substantial amount, depending on the model.

The combination of a crane with a truck chassis offers excellent mobility. The truck enables the crane to be quickly transported to different job sites.

A well-designed hydraulic system powers the crane's operations. The hydraulic pump, driven by the truck's engine through a power take-off (PTO), pressurizes the fluid. This fluid then controls the hydraulic cylinders that move the boom and rotate the crane.

Outriggers are a crucial safety and stability feature. These extendable arms deploy from the sides of the truck to provide a wider base of support during lifting. The outriggers have adjustable feet to adapt to different ground conditions.

The cab is designed with the operator's comfort in mind. It has an ergonomic seat and a well-laid-out control panel. The controls, including joysticks and switches, are intuitive, allowing for easy operation of the crane and truck.

Truck-mounted cranes come equipped with various load-handling devices. Hooks, usually made of high-strength alloy steel, are used to attach to the load. Slings and spreader bars are also available to secure and distribute the load properly.