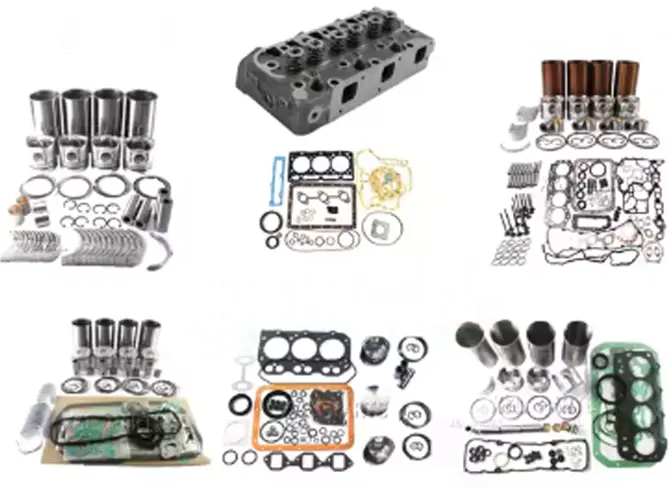

A well-designed piston with a proper fit in the cylinder reduces friction. Low-friction piston rings are used to create a good seal between the piston and the cylinder wall. This seal is vital as it prevents the leakage of combustion gases.

The cylinder walls play an important part in heat transfer during the combustion process.

The intake and exhaust valves are responsible for controlling the flow of air and fuel into the combustion chamber and the expulsion of exhaust gases.

The injectors must atomize the fuel into very fine droplets to ensure good mixing with the air in the combustion chamber. Fine fuel droplets have a larger surface area, which promotes more efficient combustion.

The crankshaft and connecting rods convert the reciprocating motion of the pistons into rotational motion.

When sourcing engine parts, it's advisable to opt for parts from well-established manufacturers. Brands with a long-standing history in the industry have a reputation to uphold. Reliable engine part manufacturers adhere to industry-recognized certifications and standards.

One of the safest ways to source engine parts is through authorized dealers and distributors. These entities have a direct relationship with the manufacturers and are more likely to supply genuine products.

Genuine engine parts usually come in high-quality packaging. The packaging material should be durable and well-printed.

Engine parts have specific dimensions and tolerances that are crucial for proper operation. Genuine parts are manufactured to exact specifications.